In an era where movies and video games use computer-generated images to create realistic scenes, it should be no surprise that the same technology has found a home in maritime training.

This has long been the dream across multiple industries. For instance, one of the first government computer research programs after World War II aimed to provide navy pilots with a realistic simulator that would let them hone their skills without putting them right into the cockpit.

Even before the covid-19 pandemic, technology and training organizations were hard at work strengthening simulation technology and broadening the training it covers.

“Simulator technology can have many applications that are mostly motivated by the ability of technology to improve the workflows while staying cost-effective,” said Andrey Kazakevich, head of production at software development company HQSoftware, based in Tallin, Estonia and New York City.

After all, providing an immersive augmented reality/virtual reality presentation of a product or training simulation often costs less than holding an in-person, real-world experience. After the initial setup is covered, recurring expenses are minimal.

His company has worked with an energy firm that builds floating production storage and offloading units for the oil industry. To give a presentation of the unit, HQSoftware developed an augmented reality-powered 3D model that demonstrated the scale and the detail of the project through a mobile app.

For companies focused on the maritime training and simulation space, the state of the art has advanced at a breathtaking pace. At VSTEP, a maritime simulation company based in the Netherlands, the focus is on enhancing the user experience and providing “unencumbered access” to its maritime simulation software, said Stephen Kelly, senior business development, Americas. With access to VSTEP’s cloud-based NAUTIS maritime bridge simulator, for example, mariners are no longer restricted to training at a physical location. They can access its simulations from anywhere, at any time.

“In concert with our push to the cloud, we aim to prepare the future mariners for the types of technology they will encounter while at the helm of a vessel,” Kelly said. In partnership with Smart Ship, VSTEP is working to integrate tactile feedback into its simulations. NAUTIS bridges transfer crucial information to the maritime operator through forces and/or vibrations during complex operations that can increase situational awareness. Kelly believes this “haptic” feedback will make training safer and more efficient.

Many maritime incidents are traced back to human error. Integrating the tactile response into the NAUTIS maritime simulators can provide intuitive feedback, allowing for automated learning. “The merit of haptic feedback goes beyond training and can also be incorporated in actual vessels to guide sailors through their voyage,” Kelly said. “The technology has the potential to minimize risks and reduce chances of accidents as it can render guidance to captains during their sailing by providing tactile feedback when they make a wrong move or are too close to shore.”

Phil Thompson, director of simulation, training and surveys at BMT Group, said there are two factors driving maritime simulations — in addition to the value of remote learning.

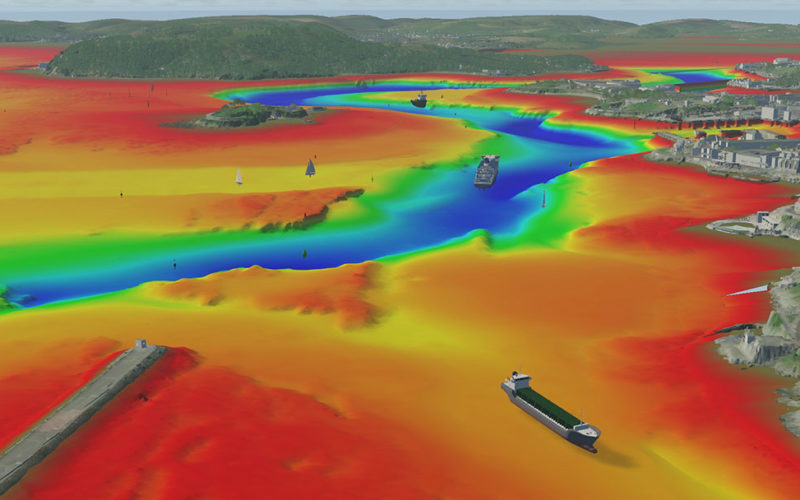

First, there are new and emerging hydrographic standards for data visualization and exchange such as the International Hydrographic Organization S-100. “These new marine data standards open-up opportunities and requirements for maritime and navigation simulators to display more granular and dynamic data, including bathymetry, surface currents and water level information,” Thompson explained. This will in turn accelerate the introduction of more precise passage planning, under-keel clearance management and simulation-based training platforms. He believes it will accelerate the synthetic environment modeling of increased levels of autonomous ship navigation.

Second, according to Thompson, there are developments in digital forensics and lessons learned in simulator functionality. These allow developers to rapidly create 3D reconstructions of actual incidents at sea using VDR and AIS data, among other sources, to re-play incidents. Mariners using the program can pause and take control, switching from a passive reconstruction to a fully interactive simulation using a real-world event as it happened in real time. This will let users test other scenarios as part of a powerful “lessons learned” exercise.

Working remotely is a new normal for many industries, especially in education and training. The covid-19 pandemic has further reinforced the need for remote solutions, allowing mariners to train from home, the company office or anywhere else in the world.

“In the past year, we saw an outstanding interest in remote training possibilities coming from maritime schools and academies as they were forced to close due to pandemics,” Kelly said. As mariners become more accustomed to these programs, and the technology itself continues to improve, remote simulation likely will play a larger role in the commercial shipping industry.

“We see it having multiple roles. Learning and training new skills, evaluation of performance, onboarding new hires, [and] bridging the knowledge gap of the seafarers,” Kelly said.

The emergence of offshore wind power in the United States and other developed economies around the world has driven the need for specialized training in these fields. One example is “Walk to Work” led by the class society DNV to assist offshore facility operators in achieving safe and efficient personnel transfers using gangways. Other training needs include offshore wind maintenance, installation and sub-sea operations.

“To install, service and maintain these installations, mariners turn to physics-based simulators to mimic environmental and operational conditions so they can complete their work safely,” Kelly said.

Elsewhere in the industry, companies are working to re-create waterways and ports in a maritime environment tailored to the customer’s needs. Bohemia Interactive Simulations, a software company based in Orlando, Fla., is developing virtual training exercises that mirror actual harbors, ports and waterways where the mariners work.

Oli Arup, senior vice president of product management at Bohemia Interactive, said the company achieves this by identifying and obtaining GIS and model source data, building a process to create the terrain, then refining both the source data and the resulting virtual terrain to meet user requirements. A process that used to take weeks or months of effort can now be available essentially on-demand.

“Within 10 seconds,” he said, “you can train anywhere in the planet.” •