A slippery coating that mimics the pitcher plant could help solve marine biofouling, a major economic and environmental problem impacting vessels of all sizes worldwide.

“Slippery surfaces, inspired by the slick lip of a (Nepenthes) carnivorous pitcher plant that sends insects sliding down to their doom, take advantage of the fact that it is very difficult for an organism to attach to a liquid surface,” said Joanna Aizenberg, professor of chemistry and chemical biology at Harvard University and director of the biologically inspired materials lab where the SLIPS (slippery liquid-infused porous surfaces) technology was invented in 2010 and incubated until 2014.

The lubricant-infused coating, developed by Adaptive Surface Technologies (AST), is in testing at 10 sites worldwide with plans for commercialization next year, said David Ward, chief executive officer at the Cambridge, Mass., company.

AST received a $2.9 million grant from the Advanced Research Projects Agency-Energy (ARPA-E), part of the U.S. Department of Energy, to develop and test the coating for recreational, commercial and military vessels. The company has received $8.9 million in funding from private and government sources, including the Massachusetts Clean Energy Center.

“ARPA-E’s funding of AST’s SLIPS technology has facilitated the development of a potentially transformative, energy-saving marine coating,” said Dr. Joseph King, the agency’s program director. “A key element is that it’s non-toxic, in contrast to many current marine anti-biofouling paints. Its lower drag helps ships save on fuel, with concomitant reduction in biofouling allowing ships to stay in service longer between scheduled maintenance.”

|

|

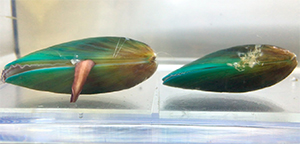

An Asian green mussel’s foot protrudes from its shell to probe the surface of a test panel, evaluating whether it can attach threads. Researchers found that lubricant-infused surfaces physically interfere with a mussel’s ability to detect the solid surface beneath it, disrupting the threads. |

|

Courtesy Nanyang Technological University, Singapore |

SLIPS consists of a film of lubricating liquid locked in place by a submicro porous layer, creating a smooth, stable interface that can be made optically transparent, the researchers wrote in the September 2011 issue of Nature.

In joint research by Harvard University and Nanyang Technological University of Singapore, researchers found the SLIPS technology can prevent the extremely aggressive Asian green mussel from attaching to submerged solid surfaces. This is possible, the researchers state in the August 2017 issue of Science, “by deceiving the mechanosensing ability of mussels, deterring secretion of adhesive threads.”

The Asian green mussel is considered one of the worst biofouling culprits, costing the shipping industry an estimated $40 million annually. While SLIPS technology has previously been shown to be effective against bacteria and algae microfoulers, the joint research found that it could also repel hard-shelled macrofoulers, including barnacles and mussels.

“While many biofouling organisms adhere to underwater surfaces in different ways, the SLIPS technology could work across most species,” Aizenberg said. “Through a detailed study using mussel adhesion as in critical proxy … we came to understand the mechanism of how mussels attach themselves to a surface and how it can be prevented, from the nanoscopic to the macroscopic scale. We now have a very detailed understanding of fundamental science coupled with successful, real-world applications.”

The cost of attachment

“Irrespective of what paint covers the bottom of a ship’s hull, slime and barnacles can accumulate, and if you don’t clean it off, it slows the vessel down,” said Andy McNab, operations manager for Cooley Marine Management in Stratford, Conn., which is testing the SLIPS coating.

“There’s a lot of interest in tackling the problem,” said Joseph Lomakin, director of biofouling business at Adaptive Surface Technologies.

Fuel represents as much as 60 percent of total ship operating costs, according to the World Shipping Council, and industry experts estimate that up to 15 percent is wasted due to biofouling. Data from a recent ExxonMobil study and the U.S. Energy Information Administration show that the global maritime industry spends about $100 billion a year on fuel.

AST calculations have shown that SLIPS technology could reduce global energy use by an estimated 1.1 quads (1.1 quadrillion British thermal units) per year and also reduce carbon dioxide (CO2) emissions by an estimated 107 metric tons annually.

Real-world testing

Following two years of testing with the U.S. Office of Naval Research, the AST team is testing the technology in five high-biofouling locations — Florida, California, Massachusetts, southern India and Singapore — and is still accepting vessel owners for trials. So far, SLIPS has held up against the onslaught of marine organisms across the differing climates, faunas and water conditions, Lomakin said.

“Tests performed at sites across the world confirm SLIPS coatings have remained effective over 1.5 years and continue to operate effectively,” he said. “The coatings can be applied without ventilation equipment to any type of boat, whether wood, fiberglass or aluminum.”

|

|

Hull fouling by barnacles and other marine organisms can increase a ship’s fuel consumption by up to 30 percent, according to the European Commission. |

|

Courtesy Center for Lakes and Reservoirs |

SLIPS releases fouling easily at speeds of greater than 10 knots and can be effectively cleaned to nearly new condition with pressure washing or soft cloth wiping for all vessel types, Lomakin said.

In the past two years, Cooley Marine Management has been testing SLIPS in the field for AST. The coating has been applied on aluminum and fiberglass panels on land as well as on the hulls of four fishing boats ranging in size from a 20-foot aluminum skiff to a 50-foot vessel.

“Similar to building a new boat or repairing an old one, we start by sanding the boat, apply an epoxy primer, then a middle primer and finally the SLIPS topcoat with the middle coat chemically bonding the inner coat and barrier coat,” McNab said.

Last fall, he said Cooley crews observed substantial biofouling growth on the fishing boats but were able to wipe it off with a rag. In January, they ran another test on fishing boats operating in icy winter conditions and found no growth, he said.

While the effect on fuel usage can vary significantly by vessel type, AST predicts an average of 5 percent to 10 percent fuel savings by switching to the SLIPS coating, Lomakin said. In addition to reducing fuel consumption due to a cleaner boat, shipowners also can reduce spending on environmental measures by reducing CO2 emissions, he added.