Three years ago, following the arrival of the ASD tug Becky S., Bisso Towboat Co. President Scott Slatten said every new delivery made him feel “like a kid in a candy store.”

The following year, in 2016, the candy store featured the ASD tug Mr. Ruben. Late last year, his sweet tooth for new tugs was sated with delivery of the 100-by-38-foot Liz Healy.

In January 2018, two months after Liz Healy’s christening on the New Orleans waterfront, the tug was already hard at work in the Mississippi River. Capt. Bryan Tastet steered alongside Alma S. and Mr. Ruben to assist the loaded bulker Super Luna into the Zen-Noh grain terminal upriver from New Orleans.

“This boat has great maneuverability and horsepower,” said Tastet. “And the winch is a deck hand’s dream.”

|

|

Liz Healy is crewed by, from left, chief engineer James Jacobs, deck hand Adam Simmons, mate Michael Becnel and Capt. Bryan Tastet. |

While Alma S. pulled on the stern and Mr. Ruben tugged at the bow, Liz Healy moved into the widening space between the dock and the ship, nosed onto the ship’s bow and began pushing. The trifecta turned the ship downriver and waved goodbye.

Liz Healy was built at Main Iron Works, Bisso’s go-to boatyard for the past 27 years. In 1999, Main Iron built the 100-by-38-foot Cecilia B. Slatten — the first z-drive tug on the Mississippi. It was followed by Alma S., Michael S., William S., Becky S. and Mr. Ruben. Liz Healy, named for the company’s general counsel, is the seventh of the class.

After Cecilia B. Slatten’s delivery, Bisso Towboat acquired the design from naval architect Greg Castleman. While retaining the same 100-by-38-foot dimensions, Bisso and Main Iron tweaked and upgraded the house arrangements, bridge layout, propulsion and towing machinery, and air conditioning systems over the years. Through that process, they arrived at what is essentially an enhanced version of the second tug, Alma S., built in 2006.

There are also subtle changes, such as additional defroster vents located a little higher to better clear the windows. But in dimensions, the tugs are alike.

|

|

Capt. Bryan Tastet positions Liz Healy midships against the bulker Super Luna in the Mississippi River near Convent, La. A sister tug, Mr. Ruben, is pushing on the bow of the ship. |

When Becky S. joined the fleet in spring 2015, the most exciting upgrade from the crew’s point of view was the addition of a second head, lending credence to the cliché that two heads are better than one.

Next in succession of popularity was the addition of a 6-foot mudroom located aft of the galley between the stacks. The change allowed for moving the engine room door from the galley to the mudroom, greatly reducing the noise in the crew quarters.

To combat the steamy Louisiana summers, when AC and hot air compete for dominance, Bisso adopted a keel-cooled air conditioning system on William S. that has been used on newbuilds ever since.

“It’s extremely efficient,” said Capt. Jon Davis, Bisso’s vice president of engineering. “The forced air is constantly being cooled by the river water.” Davis noted the system also reduces maintenance costs.

Liz Healy’s propulsion comes from two Caterpillar 3516 Tier 3 mains and Rolls-Royce US 205 FP z-drives with 90.5-by-82.25-inch propellers. That arrangement produces 60 tons of bollard pull.

Starting with Michael S. in 2010, Bisso Towboat began using Caterpillar engines, freeing up engine room space. Also, all connections for hoses, fuel, water and oil discharge were made accessible from outside the engine room, relieving the engineer from having to drag hoses around the machinery within the room.

Bisso also reconfigured the duct work for the engine room blowers on Becky S., installing a curved port duct that directs the air forward, combined with a perpendicular starboard intake duct that creates a draft all the way forward.

The Rolls-Royce z-drives on Liz Healy are ice class, built heavier than normal for heavy duty and longevity. The Kort nozzles are stainless steel to ward off the effects of electrolysis. “Electrolysis will eat up the nozzles if they’re not stainless, and the longevity will offset the initial cost,” said Tastet.

|

|

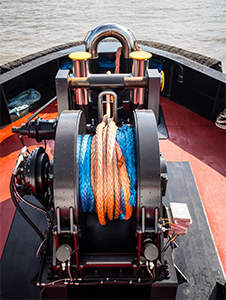

JonRie supplied the Series 230 bow winch on Liz Healy. |

On Becky S. and subsequent tugs, Bisso replaced the Markey bow winches with JonRie Series 230 hydraulic auto-tensioning hawser winches wound with 500 feet of Samson 8-inch line. The winch is equipped with pedals at the helmsman’s feet. “They free up the hands when paying the line in and out while working a ship,” said Tastet. “With all the other things that you have to take care of while working a ship, it’s a real help.”

Standard equipment on a Bisso Towboat bow is a stainless-steel H-bitt and a stainless-steel staple on the bow stem. A Washington Chain & Supply RSRH-100 100-ton capacity, quick-release pelican hook and a stainless-steel H-bitt are standard on the stern. Main Iron included an aluminum grill between the stacks, a bit of a lagniappe the yard builds into all its tugs.

The shoulder and quarter bitts are also stainless steel and slanted inboard, as are the bulwarks, in order to tuck more easily under a ship’s counters.

“Being a tractor tug, the boat is so much safer than a conventional boat,” said Ruben Dupre III, Bisso Towing’s vice president, safety and control. “We can go a lot of places conventional tugs cannot.”

|

|

Bisso Towboat has used Caterpillar engines aboard its ASD tugs since Michael S. in 2010. The updated Cat mains aboard Liz Healy each generate 2,240 hp. |

M&M Bumper of Bourg, La., custom designed and fabricated the fendering on Liz Healy. “We build it by hand,” said company President Robyn Gonsoulin. “The 22-inch thick bow fender, combined with the bulwarks and the hull fender, is constructed as an all-in-one unit. Building a fender this way is not an easy task. The bow fender alone uses 892 truck tires and weighs in at over 20,000 pounds.”

M&M also fabricated a 24-by-11-inch-thick laminated stern fender. The rubber is trimmed by hand to fit the vessel, and the 42 recycled aircraft tires are pre-rigged with galvanized steel chain and shackles to reduce labor at the shipyard.

Liz Healy’s pilothouse, finished in Spanish cedar and surrounded by abundant glass, is a signature of Main Iron’s approach to quality finishing. The four staterooms located below the waterline also are finished in Spanish cedar.

Introducing the first ASD tug to the Mississippi River in 1999 was a significant move at a time when there was widespread skepticism about z-drives. Many wondered if the propulsion system could withstand the river’s notorious currents and abundant debris.

|

|

The highly polished stainless-steel staple and bitts add strength and prevent chafing. |

Dupre III is the son of Ruben Dupre Jr., namesake of the tug Mr. Ruben, who held numerous positions with the company from 1981 until his retirement in 2015. He also played an integral role in growing and modernizing the company fleet, including its decision to build Cecilia B. Slatten.

“He and I were the ones who put our necks on the line back in 1997 when we convinced our president at the time, my father, Capt. Billy Slatten, to build the first ASD tractor tug for use on the river,” Slatten said. “I’ll never forget when he told us both, ‘If these z-drives don’t work out on the river, you’re both gonna be looking for a job.’”

Having crossed the ASD threshold, the next challenge will be updating the class for Tier 4, and the difficulty of shoehorning new equipment into the machinery spaces without major design changes. “We really like this tug design and want to keep it with Tier 4 propulsion,” said Slatten.

Currently the 12-boat Bisso Towboat fleet is over 50 percent ASD-driven. The company is committed to z-drives, which Slatten said have proven admirably suited to ship-assist work in tight spots and in the river’s difficult currents. They’re also not as vulnerable to river debris as once thought. “Eventually we would like to have a 100 percent ASD tractor fleet.”