Tugboat watchers familiar with the brilliant blue-and-yellow profile of Western Towboat’s Titan class ocean tugs plying the West Coast will do a double take at the silhouette of Hyak Maritime’s two new tugs, Hawaii and Washington. Both tugs have almost the same profile as the Western Towboat tugs, but they are on long-term charter to Crowley Maritime and carry that company’s distinctive bright red stacks.

The 120-foot Hawaii was delivered last year, and Washington finished sea trials on the Columbia River in April at the JT Marine shipyard in Vancouver, Wash.

The Seattle-based Western Towboat vessels are employed on a weekly scheduled run, towing freight and rail barges between Seattle and Southeast Alaska. “The Hyak tugs are working projects requiring various types of towing in support of offshore construction, pipe laying, offshore installations and towing the (Crowley) 455 series barges,” said John Ara, VP Crowley Solutions.

|

|

Illustrating the changing times, Washington sits next to Sea Prince, a 50-year-old conventional tug that was state of the art in its day. |

“I’m going down the states to name them until I run out of states,” said Robert Dorn, co-owner with Gordon Smith of Hyak Maritime, a company they formed in 2012. The partners have options for two more boats, which, if built, will be named Montana and Alaska. Dorn expects to be building more of them to begin replacing an aging U.S. coastal and ocean towing fleet. “There is a hole out there for tugs with safe modern equipment,” he said.

The Hyak partners are well versed regarding ocean towing vessels. Dorn was CEO at Sea Coast Towing, and was a partner with Smith at Sirius Maritime, both ocean towing companies based in Seattle. Both companies were acquired by K-Sea Transportation in 2005 and 2007, respectively, before K-Sea was, in turn, bought by Kirby Corp. in 2011.

“We surveyed all of the U.S. ocean towing company’s equipment in 2011,” said Dorn. He explains that the industry has done a very good job of modernizing its barge fleet, and that there is a good representation of new assist and escort tugs. “But few companies besides Western Towboat are building line haul boats,” he said.

“In the U.S. flag fleet, the 4,000- to 6,000-hp ocean and coastal towing fleet is the single oldest class of boats, at 35 to 40 years old. They need replacing, especially in light of the new environmental, technological and crew-comfort issues.”

Not surprisingly, the Hyak boats are based on Western Towboat’s Titan class of tugs. “Ric and Bob Shrewsbury at Western are tugboat men that know how to build the right boats for performance and longevity,” said Dorn. “And their engineer Ed McEvoy is a genius. I joke that we’ve gotten $50 million of free R&D from them. They’re the top tug guys in my book.”

|

|

Washington is equipped with a JonRie Series 200 hawser winch that will carry 600 feet of synthetic line. For safety, all of the winch operations can be controlled from the pilothouse. |

The Titan-class Western Towboat tugs were co-designed by Jensen Maritime and Western Towboat, and they have been improving on the design tug by tug, as they are built at Western’s shipyard on Seattle’s Lake Washington Ship Canal. Dorn and Smith obtained the licensing from both companies to use the Titan design. “We continued with using the Titan classification for these boats as a homage to the Shrewsburys and McEvoy,” said Dorn.

Jensen Maritime, a Crowley company, is also designing the Hyak boats with Tullio Celano, a professional engineer, serving as Hyak’s representative and technical advisor, primarily reworking items from the original design and providing production support.

There are some visual and mechanical differences between the two fleets. Most notable of the differences from a visual perspective, aside from color, is the pronounced rakish slant of the stainless steel stacks on the Hyak boats. As for machinery, the Hyak tugs have a pair of GE 8L250 mains turning Schottel 1515 FP z-drives, as opposed to Caterpillar C175s in the Western boats.

Dorn considers the Alaska run that Western performs month in and month out, in all weather, as difficult a coastal towing voyage as there is on the planet. The yellow and blue tugs are turning 420-by-105-foot rail and freight barges between Seattle and the demanding port of Whittier, Alaska, on a weekly schedule, crossing the nasty Gulf of Alaska at 10 knots and mooring the barges without assist tugs. To that end, the Hyak tugs had to be designed for towing in the open ocean and for pushing barges on inside waters.

According to Dorn, the Western Towboat design is the perfect combination of power, speed, efficiency and maneuverability for coastal towing.

The essential elements of the 4,000- to 6,000-hp tugs, comprising the bulk of the U.S. coastal barge fleet, meet the present and long-term requirements of the sector, but they are inefficient and costly to run and maintain.

“But the new propulsion efficiencies required and installed in the Hyak vessels mean that the fuel, maintenance, repair and operating costs will be substantially lower,” said Dorn. The boats are also much safer and a lot more comfortable for crews than those in the aging fleet.

|

|

The bow staple. |

“And this design hits the sweet spot at 91 U.S. regulatory tons and 497 International tons,” said Dorn. “Under 100 U.S. tons keeps the required crew complement at a potential of four, an enormous labor cost savings.

“The boats are SOLAS IMO qualified, but staying under 500 International tons means the boats are not required to have separate generator rooms or a motorized lifeboat and a number of other things. They can go anywhere in the world.”

Dorn and Smith intend for Hyak to become the go-to company for long-term bareboat charter and for their Titan class to be the tugs of choice for ocean towing. “We don’t want to compete with our customers, so we’re not building the boats to operate ourselves, but to lease out,” Dorn said.

At sea trials in June 2013, Hawaii’s bollard pull was measured at 82.5 tons. It had a free running speed of 14.5-knots. The performance exceeded the partners’ expectations for pulling a loaded 420-foot barge at 10-knots, and confirmed for them that the fuel efficiency of a 4,000-hp boat was realized in a 6,000-hp tug.

The GE four-stroke, medium-speed engine is 18 percent more fuel efficient than a similar horsepower four-stroke, high-speed engine, according to Dorn. Unlike the standard propulsion package of two-stroke, medium-speed mains, the GE consumes no lube oil. Compared with the tugs in the Sea Coast and Sirius fleets, Dorn contends that the savings on fuel and lube oil in the new tugs are significant.

The 20-year maintenance schedule on the GE engines indicates 40,000 hours before needing a top end first inspection. “That’s six or seven years for most line-haul operations,” said Dorn. “I’ve heard from Crowley that they are burning 1,500 gallons less fuel per day compared to the last generation of line-haul tugs. And they’re not using much lube oil.”

Brandon Durar at JonRie has been working closely with Dorn on the Titan tugs to redesign the winch systems for ocean-class towing. For boats that operate at sea and are therefore unreachable for repairs, the primary modifications to the winches are independent operation and redundancy, a system that Durar has dubbed JonRie unclutched.

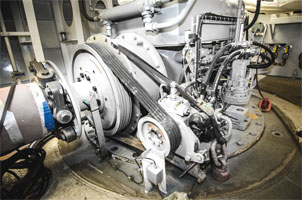

|

|

One of the two four-stroke, medium-speed GE 8L250 engines. They generate a total of 5,358 hp at 900 rpm. |

“To that end the Series 500 double-drum towing winch on the stern has independent towing drums,” said Durar. “If anything happens to one drum, the other has its own motor and any job out in the ocean can be completed.”

Each drum is also powered independently, utilizing pumps on each of the John Deere 6081 Kohler gensets, creating redundancy in case of a pump failure.

“When both pumps are clutched in, they will produce 400-hp of power to the winch producing extreme speed and line pull,” Durar said.

The winch also features a controlled free-wheel system that allows the operator to pay out the line as quickly as necessary and then feather it back. The drums are wound, one with 2,400 feet of 2.25-inch wire, and the other with 1,800 feet of 2-inch wire.

On the bow is a JonRie Series 200 hawser winch, also independently powered, and wound with 600 feet of synthetic line.

All of the operations for both winches can be operated safely from the pilothouse. “The level wind on the towing winch is also an independent drive, so no one has to be on deck to make adjustments,” said Durar. He added that the level wind can be operated in auto mode to synchronize the line on the drum with the winch’s joystick. Or you can run it manually. It has the ability to move back, forward and be stopped as you spool against the flange.

|

|

Carbon fiber shafts and couplers connect the engine to Schottel 1515 FP z-drives. During sea trials Hawaii’s bollard pull was measured at 82.5 tons. |

The unclutched ship set supplied by JonRie includes the independently powered capstan that can be engaged whether or not the other winches are in use.

Greg Armfield, co-owner of Schuyler Rubber, reported that the Woodinville, Wash., company provided its model SR3D-2 double-loop fenders for the main upper bow area and model 100A solid-type fenders for the lower bow and stern sections. As another nod to Western Towboat, a row of rigidly fixed airplane tires line each side of the hull. Dorn, like the Shrewsbury brothers, dislikes the clanking of chain-fastened tires in the night.

Crew safety and retention have become major factors in crewing workboats of late. Recruiting crewmembers is a challenge, and training them is costly, making retention a major goal. Crew comfort is an important factor in that regard, especially in ocean towing where members have to make the tug their home for long periods, in all types of weather.

“We are using the Norax system of insulation in all of the bulkheads, overheads and floors in the living areas,” said Dorn. The panels are sound attenuated and fireproof, and the living area is very quiet. It is the same system as is used on cruise ships.”

The Titan tugs will carry ABS Maltese Cross A1 and Towing Service certifications that will allow them to tow internationally. At Western Towboat, the Shrewsbury brothers’ mantra is “easy maintenance and simplicity,” and they build their boats to last. The Hyak boats, Hawaii and Washington, follow suit. Dorn is confident that Hyak’s goal of adapting the design of Western Towboat’s proven tugs to encompass a broader range of ocean and coastal towing applications has been met.