When Newcastle Shipyards was approached to build Harbour Island, the brief was simple: build a go-anywhere, finely finished, charter-ready yacht with a shallow draft. The client, an experienced boater who grew up cruising around Florida and the Bahamas, selected the Palm Coast, Fla.-based yard for its expertise in building expedition boats.

As is the case with many megayacht projects, Harbour Island began as a 164-foot design but grew in length as the build evolved. Construction was well underway on the steel hull and aluminum superstructure when the decision was taken to add a 16-foot extension at the stern. There were two reasons: to satisfy the owner’s request for more usable aft exterior space, and to increase the yacht’s hull and superstructure length, improving its profile and proportions.

|

“The extension also increased the length of her waterline and ensured that the desired 12-knot cruising speed could be maintained,” said Capt. Rafe Palladino, who logged nearly 4,000 nautical miles on the boat’s first trans-Atlantic voyage, burning between 58 and 63 gallons per hour at between 1,150 and 1,200 rpms.

Murray & Associates of Fort Lauderdale were the naval architects. “In the end we met the speed we set out to achieve and the extension didn’t adversely affect her performance. In fact, it slightly improved her hull speed,” said Luis Martinez, the chief naval architect. “We were very satisfied by the outcome.”

|

|

|

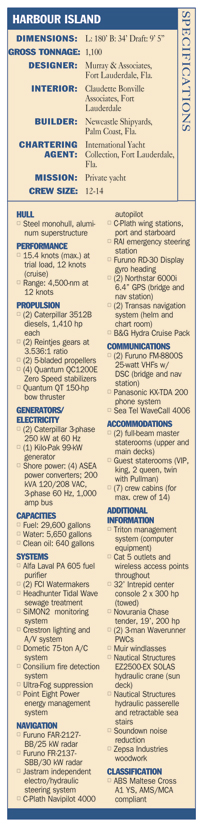

Space and elegance (and expense) are the hallmarks of a megayacht, with a fully finished bridge (aboe) and gleaming engine room (top). Cruise speed is 12 knots, with power supplied by two Caterpillar 3512Bs. |

Harbour Island is a full-displacement yacht with a gross tonnage of 1,100. As such, it’s not only the largest yacht by length to be built in Florida (and the largest built by Newcastle), it’s also one of the most voluminous yachts built in the United States. Its five decks feature more than 10,000 square feet of living space and nearly 8,000 square feet of interior space. The sense of spaciousness is immediately apparent from a side effect of the stern extension: a massive tender garage.

The garage houses a 19-foot Novurania Chase tender and two Waverunners, all easily maneuvered, stored and deployed via a unique air cradle system developed by Craig Tafoya and his company, Penumbra Marine Logistics. “All you need is a smooth deck surface,” said Tafoya, a former superyacht captain who has built custom air-powered units for storing and launching tenders, toys and even gym equipment for builders such as Trinity, Feadship and Nobiskrug.

The air-cradle system operates much like a hovercraft: air pressure allows the tender or toy to be maneuvered into position and lowered at the touch of a fingertip. The system not only reduces the risk of injury, it saves the crew space and time, a key factor with any charter yacht. The air cradles can be easily stowed away when the tenders and toys are deployed, allowing the garage to be used for entertaining.

The stern extension also created enough space for a sizeable engineer’s cabin and technical space aft.

A close look at the systems and equipment installed aboard Harbour Island might suggest that this is a yacht intended for heavy-duty expeditions rather than for regular charter service and casual cruising in the Bahamas.

There is also a level of redundancy built into the systems. Harbour Island is equipped with a SiMON2 integration and control system that can monitor more than 560 parameters on board, including security. It was designed for iPad use, so the captain and engineer can control any of the yacht’s functions remotely. Chief Engineer Kirk Graham is able to drive the boat directly from his engine control room in the event of bridge equipment failure. “I can monitor the speed and the heading with the SiMON2 system,” he said. And he points to a triple redundancy: an aft steering station as well.

An advanced computerized energy management system designed by Reagan Equipment Co. and Point Eight Power ensures a seamless transfer from generator to shore power. Harbour Island is also equipped with reverse-osmosis watermakers and an environmentally friendly oily water separator that meet the criteria designated by the American Bureau of Shipping (ABS), for which the yacht is classed.

The main engines and generators are gravity fed their fuel from a bulkhead-mounted day tank. Fuel is continuously polished by an Alfa Laval system, which keeps the 3512B, 1,410-hp Caterpillars operating at peak performance. The yacht is equipped with a Maritime Coastguard Agency/Cayman Islands Shipping Registry (MCA/CISR) Consilium fire detection system, which is supported by an Ultra-Fog sprinkler system throughout the boat.

Above the waterline, Harbour Island is tailored toward onboard comfort for the vessel’s owner and guests. The hull design provides a stable platform, assisted by four-fin Quantum Zero Speed stabilizers. Murray & Associates and the build team also minimized noise and vibration. Soundown sound damping material was applied throughout the boat, including the crew areas, and the exhaust system was supported from below to minimize vibration through the main deck structure. “She is very, very quiet,” said Martinez.

During sea trials the team tested the decibel levels in the main saloon, just above the engines. “The noise we could hear was a white noise from the air-conditioning instead of the actual engine noise,” said Martinez. “We were extremely happy with that.”

|

|

Crew size is 12 to 14. The yacht can be driven from the bridge, the engine control room or an aft steering station. |

Harbour Island’s stern extension was not the only significant design change. The captain’s cabin was originally situated on the starboard side of the upper deck, with the wheelhouse half a deck above, which meant using two staircases to access the decks. So the wheelhouse was raised to capture enough space beneath it to fit the captain’s cabin on the port side and add a much-needed A/V room. “As technology and trends evolve … owners are expecting much more out of their lighting and electronics package,” said Martinez.

This move increased the height of the sky lounge aft, giving it a cathedral-type ceiling nearly 10 feet high. Designer Claudette Bonville executed the interior design and space planning aboard Harbour Island, and she said the overhead treatment of the sky lounge was one of the project’s toughest challenges; in the end, the ceiling features a dramatic backlit dome. This area also has a 90-inch drop-down screen and overhead projector for movies. The furniture rotates 180 degrees to face the screen, and a bar and large crew pantry complete the experience.

Zepsa Industries of Charlotte, N.C., did the woodworking throughout the guest spaces, which are designed to accommodate 14 in six staterooms, including a main-deck master suite. The stonework used aboard is solid, and each space is not only beautifully decorated, but designed to facilitate crew functions.

A DC-powered seakeeping switch located in each area locks all accessories, drawers and cabinetry in place while underway, saving the crew valuable prep time. Crew flow was also considered, and there are separate crew entrances for provisioning and private stairs to avoid going through guest areas.

In places where the windows are not easily accessible, Murray & Associates incorporated high-pressure water nozzles inside the portholes to rinse the salt spray from the glass. “This is not only a safety consideration for the crew,” said Martinez, “it is a nice feature as well.”

|

|

Chief Engineer Kirk Graham in the engine room. A midcourse design change created space for a sizable engineer’s cabin and technical space aft. |

The tiered sun deck aboard Harbour Island commands the most attention, with a cascading waterfall on the aft face of the spa pool providing the welcome for guests climbing the stairs from the upper deck. Midships is a covered bar, and on top of the wheelhouse forward is a raised sunpad area. This was made possible by the relocation of the captain’s cabin and wheelhouse; because all of these spaces were structurally tied together, the design team was able to develop the sun deck as a split-level arrangement. The spa pool and its swim-up bar were placed in the center, which allowed for the waterfall, as the aft bulkhead lines up with the pool’s edge.

In the end, the owner took delivery of a boat with a 9.5-foot draft that met and exceeded his brief. Harbour Island is not only finely finished with an efficient design and features, it has the go-anywhere capabilities of an expedition vessel.