In February, the parking lot at Nichols Brothers Boat Builders in Freeland, Wash., had few vacant spaces. In good part, that was because Seattle-based Harley Marine Services (HMS) had contracted for two 100-by-40-foot ASD tugs to be built at the Whidbey Island yard. The tugs, Robert Franco, and Ahbra Franco, are named for the son and daughter of Harley Marine’s owner, Harley Franco. The boats are scheduled for delivery by late spring and mid summer, respectively.

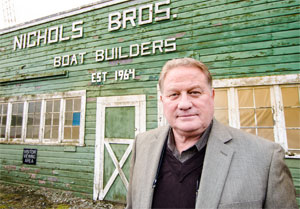

“When the parking lot is full, it is just perfect,” said Nichols Brothers CEO Matt Nichols from his office, complete with a magnificent panoramic view of the Holmes Harbor marine-scape. “Having 290 employees is very comfortable for us.”

|

|

One of the two Rolls-Royce US 255 z-drives, which are powered by Caterpillar 3516C diesel engines. |

In 2008, the Texas-based development company, Ice Floe LLC, bought Nichols Brothers from the brothers Matthew and Archie (the company was established by their father Frank Nichols in 1964) and appointed Matt Nichols director of business development. He was reinstated as CEO last year.

Jensen Maritime Consultants, a Crowley Maritime company with offices on Harbor Island in Seattle, based the design of the tugs on the Valor class of ASD tug that it originally developed for Baydelta Maritime in San Francisco. Nichols Brothers built five of them for Baydelta and one for Minette Bay Ship Docking (a SMIT company since 2009) in Prince Rupert, British Columbia.

Baydelta chartered the first two, Valor and Vigilant, to Crowley Maritime for ship assist and escort duties. Valor joined Crowley’s Puget Sound fleet, and Vigilant was ice-strengthened for the company’s Alaska fleet.

In upgrading the design for Robert and Ahbra, Jensen maintained the salient features of the Valor class: high horsepower (6,772 hp) with a large fuel capacity (70,000 gallons) for long trips, comfortable crew quarters and a large engine room. Typical of the Valor class is an extended skeg for ship assist work. The two new Harley tugs have been upgraded, primarily to meet emission standards, by the installation of Caterpillar Tier 3 engines to drive the Rolls-Royce US 255 azimuthing stern drives.

|

“The only difference between them is that the Ahbra is going to have the new C175 Cats instead of the 3516s that are in the Robert,” said Gregg Nelson, vice president of engineering for HMS. “The C175s are continuous horsepower, whereas the 3516s are intermittent.”

Both vessels have two Caterpillar C9 generators and are outfitted with Mackay Marine electronics and a Technicold Northern Lights HVAC system. Each tug will be equipped with a 250-hp Flowserve fire pump and a Stang Industries monitor, specified at 1,400 gpm. One monitor, on the bow, will be remotely controlled, and the second, on the stern, will be manually controlled.

|

|

Matt Nichols, CEO of Nichols Brothers. |

Whereas the Baydelta tugs have JonRie towing winches, the Harley boats will have a Markey TES-40 single-drum towing winch with 2,600 feet of 2.25-inch towing wire, according to Nelson. On the bow, as with the Baydelta tugs, Robert and Ahbra will have a Markey DEPC-52 75-hp electric hawser winch with 750 feet of synthetic line, the specific type is yet undisclosed. A Smith Berger tow pin will round out the aft deck equipment.

Markey Machinery developed the TES-40 single-drum towing winch, equipped with a fairlead and warping head, specifically for use on ASD tugs where aft deck space is at a premium. Also, the towing and hawser winches will share a single variable frequency drive and dynamic braking resistors and pilothouse controls. The configuration eliminates equipment in the engine spaces and also reduces the cost of doubling up on equipment.

“All of the winches on these boats are electric, so there is no environmental impact,” said Nelson. “One of the big differences from the Baydelta tugs is that these boats have keel cooling instead of raw water cooling. So there is no overboard discharge.”

The tug has an extensive fendering system.

“We supplied a very large 65-foot-long by 36-inch-diameter cylindrical upper bow bulwark fender weighing 27,337 pounds,” said Kurt Grimsgaard, president of Viking Marine South of Delray Beach, Fla. “Below that fender on the bow we used 23.5-inch by 11.75-inch M series fenders vertically side by side with graduated lengths. The rest of the tug was wrapped with 14-inch D shape molded rubber fenders.”

|

|

The bow of Robert Franco ready for the 65-foot-long cylindrical bulwarks fender weighing more than 13 tons. The tug was also wrapped with 14-inch D-shape molded rubber fendering. |

At the Nichols Brothers yard, Luke Reid, the boatyard’s project engineer overseeing the building of the tugs, expressed a bright enthusiasm for the project, a mood in conflict with the drizzly and gray winter day typical of the area.

Building two or more of the same boat at a time is an obvious advantage for a shipyard in terms of productivity and cost savings. And Nichols Brothers also has a five-boat Valor-class history to build on.

“This is the seventh one of the series, and they have been good performers for us,” he said on a tour of Robert. The vessel’s hull loomed above on its blocks, its superstructure shrouded in a Christo-like wrap of plastic sheeting for painting.

“The Ahbra will be a little more robust with C175 Cats in her,” said Reid. “They’re both Tier 3 and about the same horsepower, but the C175 has a bit more performance because it has a little more air flow. We’ve been doing a little upgrading on the tugs as we go. And so far the customers have been very pleased.”

On the Baydelta tugs, and Robert, the 3516s are rated at 3,386 hp at 1,800 rpm. The expected bollard pull before testing was around 85 tons. “We ended up with 94 out of them,” said Reid. “So we hope that we’ll get over 100 from the C175.”

The tugs will be performing ship assist, tanker escort and emergency response duties on the West Coast.

The group of companies comprising Harley Marine Services represents a growing enterprise. It seems that every time you turn around there is a new Harley company or a new Harley boat being built.

Harley Franco founded Olympic Tug & Barge, now a subsidiary of HMS, in 1987 with one leased tug and barge operating in Puget Sound. The fleet was expanded in 1992 and again in 1994 when Franco began bunkering and lube oil services in the Portland, Ore., area. In 1995 Franco acquired a deck barge and began dry bulk services. Later in the decade, Olympic Tug became a petroleum transporter internationally, but especially in Puget Sound where it led the pack in that sector. A holding company was formed and Harley Marine Services was born in 1998.

|

|

Pilothouse superstructure waiting to be joined to the hull of Ahbra Franco. |

Currently HMS is the holding company for Pacific Coast Marine, Westoil Marine Services, Millennium Maritime, Public Service Marine, Starlight Marine Services, Harley Marine NY, Pacific Terminal Services and Harley Marine Gulf.

“We’re up and going and are one of the few companies with an aggressive building program right now,” said Nelson. Harley Marine Gulf was established in 2011 and now there is a Harley on every coast in the United States.