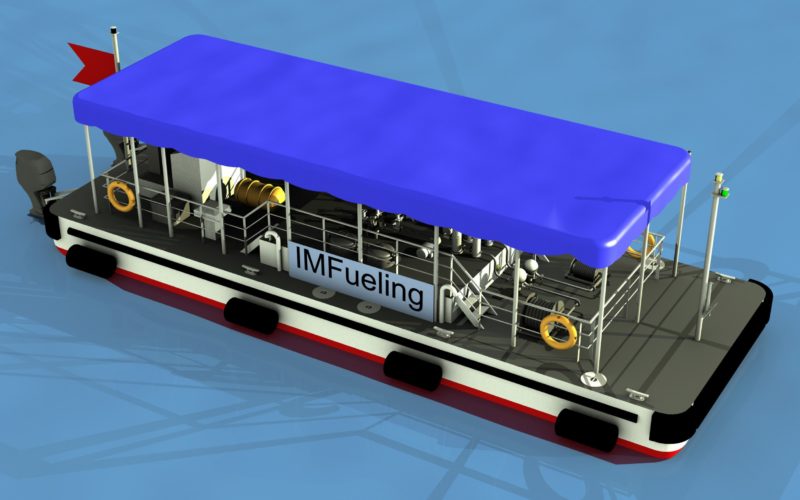

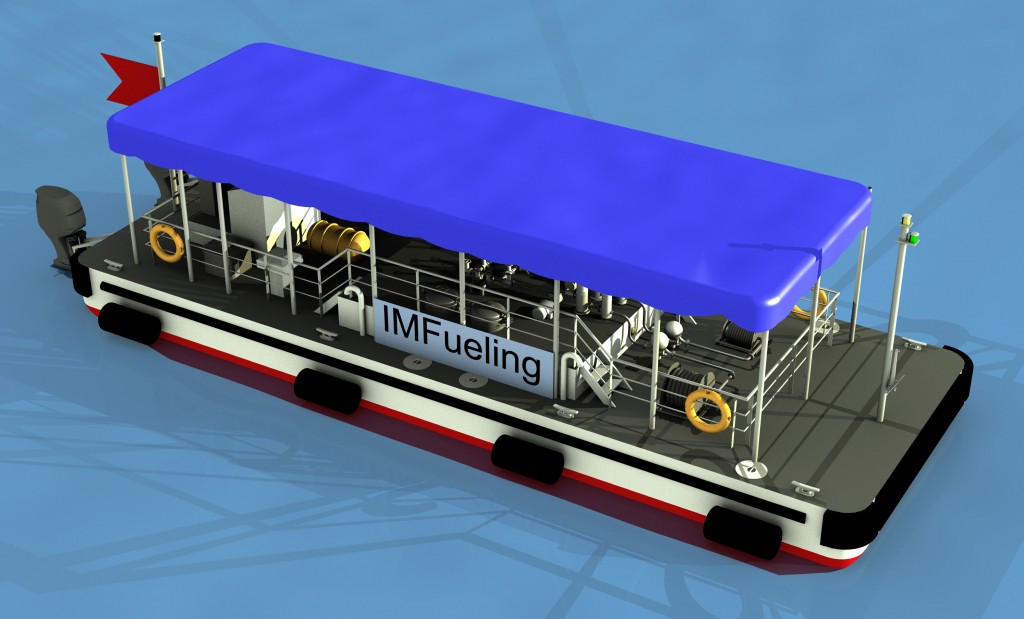

(MYSTIC, Conn.) — JMS Naval Architects has designed a self-propelled, 10,000-gallon, double-hull tankship for Intracoastal Marine Fuel (IMF) of Jupiter, Fla. The tankship design is unique for its compact size and diesel outboard propulsion.

The innovative design is the smallest vessel to receive U.S. Coast Guard plan approval as a Subchapter D tankship.

IMF will use the vessel to deliver marine diesel to megayachts, commercial vessels and recreational vessels in the Palm Beach, Fla., area. The vessel will be capable of providing fueling services where it is needed via high speed pumps, and with variable-speed control for maximum safety and efficiency.

IMF competitively awarded construction of the 53-by-18-foot tankship to St. Johns Shipbuilding of Palatka, Fla., where the vessel is under construction. The vessel is being built to ABS rules and will be inspected to 46 CFR Subchapter D. JMS is currently providing owner’s representative services on behalf of IMF during the vessel construction, testing, trials, delivery and acceptance.

Propulsion is provided by a pair of 300-hp diesel outboard engines made by COX Marine. The four-stroke, V8 CXO300 diesel outboard engine delivers a combination of high power, high torque and single fuel, enabling it to offer the same performance and efficiency of an inboard, but with the convenience and flexibility of an outboard. The outboards boast a lightweight design that requires 25 percent less fuel while delivering 480 foot pounds of torque – an excellent match for the slow-speed travel of this unique, compact tankship.

A propulsion control system made by Seastar was also selected for increased maneuverability. The Seastar Optimus electronic power steering, shift, throttle and joystick controls systems package integrates the operation of both outboard motors into a single maneuvering system.

The vessel has a raised trunk cargo tank with a pilot and operator’s station aft. The vessel is outfitted with electrically-powered cargo pumps and a 370-gallon fuel oil tank for onboard generators located below deck in the stern rake. A potable water tank and a black water tank are also located below deck and forward of the cargo tanks. The electrical system is powered by a pair of generators in the aft machinery space to provide service to the vessel’s lighting, cargo pumping, and hydraulic systems. The equipment and systems design supports high-speed loading and unloading of its cargo. A canopy is provided over most of the barge’s length including the operator’s station to provide protection to the operator from the elements. The vessel is also equipped with two 41-foot-long spuds raised and lowered by hydraulic winches in order to anchor the vessel in place during cargo transfers to customers’ vessels.

IMF expects to build several vessels of this design, with this first tankship being placed in service in the summer of 2021.