The crane barge Atlantic Giant II was rigged and ready to lift an estimated 350-ton counterweight from a salvaged derrick barge in Brownsville, Texas. But when the time came, the weight wouldn’t budge.

It remained in place with the crane set for 500 tons of tension, and again at 550 tons. After a consultation, crane owner South Coast Maritime Corp. agreed to set the crane for 700 tons of tension, its maximum working weight. While the lift was underway, at about 2030 on Aug. 9, 2018, the boom collapsed, injuring three people. Property damage was $6.4 million.

The probable cause of the boom failure, according to the National Transportation Safety Board (NTSB) was the decision to go ahead with several lifts that day that exceeded the original plan without conducting fresh risk assessments.

“There were numerous opportunities for employees to stop the work,” the NTSB said in its report. “The deviation from the planned 350 tons communicated by the client was not immediately investigated to determine the source of the discrepancy. Furthermore, there was no discussion that the 75 percent of the maximum lift (525 tons) indicated on the job-risk analysis form had been exceeded.”

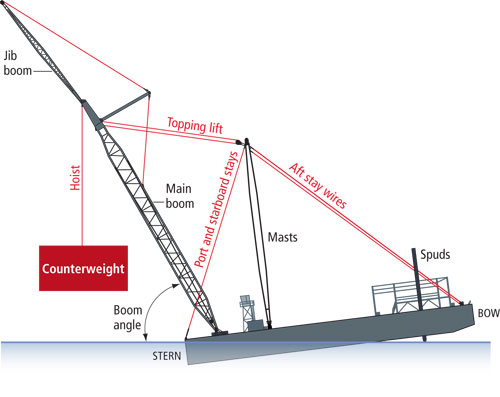

The 225-foot Atlantic Giant II was built in 2014 for South Coast Maritime, a Keppel AmFELS affiliate. According to the NTSB, the crane was mounted on a pedestal on the main deck, 25 feet forward from the transom. It had a 245-foot main boom and a 100-foot jib. Its safe working load with the boom between 66 and 75 degrees was 700 tons.

Atlantic Giant II was under contract to help disassemble the derrick barge TOPS DB1, which sank 30 miles offshore in the Gulf of Mexico in October 2017. Resolve Marine raised the barge less than a year later, performing what was reportedly the heaviest salvage lift ever in the Americas. The barge was being taken apart at SteelCoast’s facility on the Brownsville Ship Channel.

Atlantic Giant II was slated to perform a series of lifts on Aug. 9 to remove heavy components from the derrick barge. Crews involved with the job held a meeting that morning to go over the lift plan, emergency procedures and other key details. They also completed a job-risk analysis form, making it clear the crane would not lift anything exceeding 525 tons, or 75 percent of its maximum capabilities.

|

|

An NTSB diagram of Atlantic Giant II shows the barge’s position and boom angle relative to sea level as the crane hoisted the counterweight from TOPS DB1 (illustration not drawn to scale). |

|

NTSB/Pat Rossi illustration |

The first lift of the day got off to an inauspicious start. An A-frame aboard TOPS DB1 weighed 53 tons, nearly double the 30 tons that crews expected. That afternoon, after a pre-lift meeting, crews rigged DB1’s estimated 350-ton counterweight for removal. Crane tension levels continued to climb to 550 tons as subsequent attempts to lift the weight weren’t successful.

Another discussion ensued, and SteelCoast officials argued that stopping the job with the load already cut from the derrick barge would be problematic, the NTSB said. South Coast Maritime’s president then instructed the crane operator to increase tension to 700 tons. Atlantic Giant II was repositioned and made ready for the lift, which this time succeeded if only briefly. The counterweight, authorities later learned, weighed 671 tons.

“Two tugboats were used to rotate and move Atlantic Giant II and the counterweight toward the dock,” the NTSB said, adding that the barge’s two forward spuds were raised to allow for this movement. “However, at about 2030, shortly after the starboard spud was raised, the barge heeled to starboard and the crane’s boom collapsed. The port stay failed first, dropping the load into the channel.”

The crane operator on Atlantic Giant II fell to the deck, injuring his back and shoulder, and a mechanic on the barge fractured an ankle. A deck hand on one of the assist tugs also suffered a leg injury.

Keppel AmFELS conducted its own investigation of the incident and found that “wind, wave action and drifting action” affected the crane after Atlantic Giant II retracted its spuds. The NTSB determined that these factors “resulted in the suspended counterweight shifting to starboard, thereby sideloading the crane boom. Because the suspended load was not centered below the boom, the crane collapsed to the starboard side of the barge.”

NTSB investigators also learned Atlantic Giant II was trimmed up to 7 degrees at the stern at the time of the final lift, raising the bow out of the water. That trim created a situation where the 671-ton counterweight exceeded the crane’s abilities at that boom angle. Tugboat captains reported the barge’s bow coming out of the water, but the lift continued anyway. The NTSB noted that load ratings presume the crane is “perfectly level in all directions.”

South Coast Maritime responded to the incident by creating new internal guidelines that demand additional weight and structural details from clients before performing heavy lifts. Attempts to reach the company and SteelCoast were not successful.