The Columbia River Pilot felt an unusual vibration about three hours after the bulk carrier Nenita got underway.

“Hey,” he asked others on the bridge, “what happened to our engine?”

The captain spoke by phone with engineering crew working to fix the problem, but mostly in a language other than English. As the vessel lost engine rpms, speed and maneuverability, the pilot was never fully aware what was happening. Eventually, he ordered both anchors dropped and the ship ran aground.

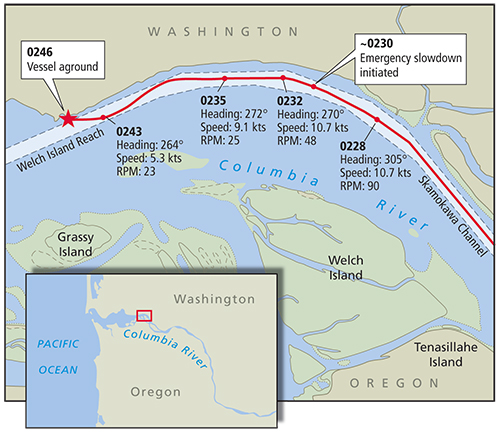

The incident, which occurred near Skamokawa, Wash., at 0246 on Nov. 19, 2016, caused nearly $4 million in damage to the ship, primarily in the bulbous bow and forward hull. None of the 25 people on board were injured.

National Transportation Safety Board (NTSB) investigators determined the failure of a main engine cylinder cooling jacket spurred an automatic engine shutdown, which reduced the ship’s speed and maneuverability.

“Contributing to the accident,” the agency said, “was the lack of information relayed from shipboard personnel to the pilot about the status of the main engine, which prevented him from taking effective corrective action following the engine casualty.”

The Marshall Islands-flagged Nenita left a Kalama, Wash., anchorage at about 2300 on Nov. 18 with a load of soybeans bound for China. The first problems arose at 0230, when the main engine cooling freshwater low pressure alarm sounded in the engine control room. Engineers found a crack in the No. 3 cylinder cooling jacket, the report said.

Cooling water was leaking from the crack, and the temperature in the No. 3 cylinder cooling water outlet rose above 203 degrees Fahrenheit, triggering an automatic engine slowdown to less than 30 rpm. Starting at 0232, when the pilot spoke of the unusual vibration, the engine speed fell from 90 to 48 rpms and ultimately dropped to 23 rpms.

The chief engineer said he relayed this information to the bridge, but it doesn’t appear the pilot knew the full scope of the situation.

“A minute and a half into the phone call with the chief engineer, the master told the pilot about a ‘leaking pipe on the main engine. … They are fixing it,’” the NTSB said. During the next 10 minutes, the conversation between the master and engineering personnel continued in their native language, which is not specified in the report. The pilot asked several times, “What’s going on with the engine?” and stated, “I need some rpms.”

|

|

This illustration shows Nenita’s trackline and speed before the bulker grounded at Three Tree Point in the Columbia River. |

|

Pat Rossi illustration |

The pilot warned the master that the vessel was at risk of grounding as the engine speed continued falling. The pilot issued a series of rudder commands to maintain position in the channel, but the vessel began drifting to starboard. The pilot ordered the anchors down and the engine to emergency full astern shortly before the ship hit bottom.

Investigators determined the pilot’s lack of information about the engine problem affected his decisions.

“If he knew the vessel was not going to quickly regain propulsion, he would have had more time to identify an anchoring location or attempt a softer-bottom grounding,” the NTSB said.

The Columbia River Pilots have since added language to pilot cards, making it clear that bridge crews must speak English in pilotage areas, the report said. The cards also note whether the ship has an engine control bypass system switch for use during emergencies.

Nenita is propelled by a single 12,378-hp Mitsui-MAN B&W 7S50MC-C diesel engine. At least two other ships in recent years were involved in accidents due to similar cooling jacket failures, according to a U.S. Coast Guard safety alert issued in December 2016. One such incident occurred on the bulker Miyama, which grounded in the Columbia River in 2015.

MAN B&W was aware of the cracking cast-iron cooling jackets. The company issued a service letter in 2014 indicating dirt and metallic pieces could accumulate between the cylinder cover and cooling jacket, reducing space between the components. According to the NTSB report, this exposed the cooling jacket to stress from heat expansion.

MAN sent the letter by mail, but Nenita’s operator at the time did not acknowledge receiving it, and the vessel’s chief engineer was not familiar with the letter. The current operator, Spring Marine Bulk S.A., took over ship operations in May 2016.

After reviewing cooling water treatment records, investigators found that chloride levels were elevated during testing roughly five months before the incident. Testing also showed levels of corrosion-inhibiting sodium nitrate were lower than recommended. Over time, the NTSB said, these factors can contribute to thermal stresses.

MAN’s letter also urged that fasteners around the cooling jacket be tightened to manufacturer specifications. Nenita’s technical manager acknowledged that did not occur on the ship. During the investigation, other engine cylinder cooling jackets aboard Nenita showed hairline cracks.

After the grounding, two tugboats towed Nenita to Longview, Wash., for temporary repairs and cooling jacket and bolt replacement. The vessel left on Dec. 8 to offload its cargo in Qinzhou, China, before undergoing permanent repairs at a Chinese shipyard.