A few years ago, as Bouchard Transportation looked to expand its fleet of articulated tug-barges, company officials were leaning toward building mega-vessels capable of moving 350,000 barrels of fuel.

But after considering the challenges, including the availability of terminal infrastructure for a barge that big, Bouchard began exploring a smaller ATB combo. As it happened, inspiration came from within.

Morton Bouchard III, president and chief executive officer of Bouchard Transportation, said the company’s 10,000-hp, 250,000-barrel ATB Danielle M. Bouchard has been one of its top performers since delivery in 1997. Now, the Melville, N.Y., company is hoping to replicate that success with its new class of ATBs.

“We signed up for one at VT Halter and started with that,” Bouchard said in a recent interview in New Orleans. “Within three months, we signed up for the second one, because the reception we were getting from the market was ‘This was the right size, there is a good need for it.’”

That decision seems to be paying off. In July 2015, VT Halter Marine of Pascagoula, Miss., delivered Kim M. Bouchard and barge B. No. 270. In February 2016, the yard delivered sister vessels Donna J. Bouchard and B. No. 272.

|

|

Capt. Bill Lawton oversaw construction of Kim M. Bouchard and Donna J. Bouchard, built at VT Halter Marine. He is the captain on Donna J. Bouchard. |

The two 150-by-50-by-29-foot tugboats have plenty in common. Both are double hulled and outfitted with the same EMD propulsion units, Intercon couplers and Nautican wheels, nozzles and rudders. They’re also both named for Bouchard’s sisters. Yet Donna has some tweaks here and there based on suggestions from Kim’s crewmembers. Extra insulation to further reduce noise and vibration is perhaps the biggest difference.

The 628-foot barges also are nearly the same, except B. No. 272 has a heater house on the deck to handle heated products.

Bouchard Capt. Bill Lawton oversaw construction of both of the new ATBs, and he said Kim is meeting the company’s high standards. During the overnight voyage from VT Halter’s yard to New Orleans in mid-February, Lawton said Donna was quiet, comfortable and maneuverable while pushing ahead at 12 knots.

“Believe it or not, it handles really good,” he said during christening festivities along the New Orleans Riverwalk. “It handled like a tugboat should handle. I was really happy that it did. It was maneuverable, it wasn’t sluggish, it did exactly what I would expect a tug and barge to do of a smaller size.”

“For speed and performance, we’re not used to having a bulbous bow on a barge,” he said, referring to the ship-like bow on B. No. 272 and its counterpart, B. No. 270. “That’s what takes it from being a barge to being a ship.”

|

|

Bouchard Transportation crewmen VAB Blake Sattler, AB Justin Nash and AB Malcolm Locke (left to right) stand aboard Danielle J. Bouchard during a christening ceremony in New Orleans. |

Sal Guarino, a founding partner of Covington, La.-based Guarino & Cox, said the Bouchard ATBs were designed for maximum efficiency, with most of the gains coming from the barges. The company used its “blended skeg” stern design to improve their efficiency in the water.

“The tug makes it into the notch and the hull of the barge much better than most ATBs,” Guarino said in a recent interview. “We designed it with as minimal as possible of a gap between the tug and barge.”

“There is very little rake because the notch is exceedingly deep,” he added. “We did that so the tug is operating mostly in the shadow of the barge, so it doesn’t have much drag. It is almost like a single object instead of two separate objects.”

Both tugboats are married to their massive barges using an Intercon coupler with 64-inch rams and lightering plates. This system allows for either a secure tooth connection or a friction-based connection in lightering mode.

“Lightering mode is designed to allow controlled changes in draft between the tug and the barge in relatively calm water,” Mike McCoy, Intercon’s president, said in an email. “In lightering mode, the rams are retracted to disengage the tooth connection, rotated 90 degrees to allow access to bronze friction plates, and re-engaged. The friction plates allow the tug to move vertically within the barge ladders while maintaining longitudinal control.”

|

|

The notched channel on B. No. 272. The tug and barge are “married” using an Intercon coupler. |

Bouchard’s faith in these Intercon coupling systems convinced the company to forgo installation of a recovery winch on both tugs. That omission saves money during construction and reduces long-term maintenance costs. It also acknowledges the winches will likely never be used.

“The tug is going to stay in that notch 99.9 percent of that time,” Guarino said. “The barge is not really designed to be towed.”

Kim and Donna are powered by two EMD Tier 3 engines producing 5,000 hp each with Lufkin reduction gears at a 6:1 ratio. Those powerful mains turn 148-inch Nautican propellers inside Nautican nozzles with triple rudders. Backup power comes from three John Deere 6090AFM75 200-kW generators, while a John Deere 6068AFM85 150-kW unit provides emergency power.

The design aesthetic of the tugboats also extends to the interior spaces, which were conceived for maximum efficiency. One example is the engine control station directly adjacent to the engine room. The electronic panel lets crew monitor key mechanical systems without the noise and heat of the engine room.

“It’s the best designed tugboat I’ve ever been on,” William Schuchert, co-chief engineer on Donna, said during a visit to that tug’s engine room.

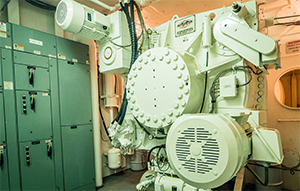

|

|

Donna J. Bouchard’s two EMD 20-710 main engines each produce 5,000 hp. |

Frank Robinson, Donna’s other co-chief engineer, said the tug is loaded with safety features, backups and redundancies.

“Everything is intuitively designed for function,” he said during a tour.

In the wheelhouse of both tugs, the captain and mate have touch-screen controls and electronic throttle systems. Both are outfitted with a Furuno electronics suite that includes radar, AIS, GPS, satellite communications and depth finder.

Based on the onboard amenities, crew comfort was an important consideration. Both tugs have five single bunks and five double rooms, all with satellite TV. The galley and mess are separate, and crew has access to an exercise room during off hours. Floating floors and extensive insulation are intended to keep the noise and vibration to a minimum.

“The creature comforts of the overall piece of equipment are huge,” Lawton said. “We spend more than half our life on these boats, so that makes a world of difference. I might not be as hard of hearing as I am now if I worked on a boat like this when I was younger.”

Kim and Donna are expected to run charters in the Gulf of Mexico, with Donna expected to move petroleum products between Texas and Florida. Both vessels have ABS A1 Towing Service, SOLAS and GMDSS certifications and can work worldwide.

|

|

Bouchard Transportation built Donna and Kim without recovery winches due to their faith in the Intercon coupler system shown here. |

“The boat can handle pretty much from cleaned oil to dirty oil. She’s going to run crude oil as well as refined jet fuel. And she has onboard cleaning capability,” Lawton said of Donna.

Bouchard, the company president, is rightfully proud of the new vessels. Although ATB tandems capable of moving at least 300,000 barrels were appealing, they would be less flexible, meaning potentially less time at work.

“The size goes by where you can get in to load,” he said during the February interview in New Orleans. “You go to 300,000 barrels, your flexibility for berths cuts down, so that cuts down utilization time. With 250,000 barrels, the infrastructure is already built for those barges.”

“She was just in the loop last week, and she pumped off 250,000 barrels in 11 hours,” Bouchard added, referring to Kim and B. No. 270. “Pumped off and gone.”

The initial success of Kim and Donna has Bouchard considering hiring VT Halter to build a third ATB in the new class.

“It’s the right time to build,” he said.