(HELSINKI, Finland) — With entry into force of the ballast water treatment regulation now less than two years away, Wartsila BWMS and scrubber retrofit engineering services are seeing considerable increase in interest in their experience and risk reduction offerings.

The International Maritime Organization’s (IMO) Convention for Ballast Water Management entered into force on Sept. 8, 2017. To meet the IMO requirements, nearly all merchant vessels above 400 gross register tonnes (gt) will have to consider ballast discharge treatment and install a ballast treatment system at their next mandatory International Oil Pollution Prevention (IOPP) survey to stop the spread of non-native species, bacteria and viruses threatening the marine ecosystems.

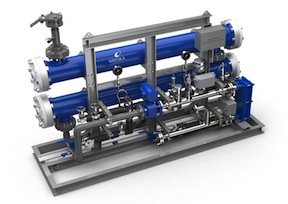

Wartsila offers shipowners and operators both proven ultraviolet (UV) and electro-chlorination (EC) technology to meet the specific operational and economic requirements of their fleet. The medium pressure UV treatment solution is mainly suited for vessels with small to medium pump capacities and uses ultraviolet light to ensure discharge compliance. The side stream EC system is used for vessels with larger pump capacities and generates naturally degradable sodium hypochlorite from the sea water to disinfect ballast discharge and ensure both ballast and International Convention for the Prevention of Pollution from Ships (MARPOL) compliance.

Both systems share a proven two-stage filtration process with a standard backwash filter system to remove particulates and sediments before treatment. Both Wartsila Aquarius technologies are IMO approved, U.S. Coast Guard (USCG) alternate management system (AMS) accepted, and both are currently undergoing full USCG and ballast discharge regulation (Revised G8). EC USCG type approval is expected to be in place during the second half in 2018, and the UV type approval in the last quarter of 2018.

Circa 26,000 ships need to comply with the new legislation

From Wartsila’s own market analysis, more than 26,000 ships above 400 gt, prepares to comply with the new environmental legislation, the demand for BWMS retrofit projects and engineering services is likely to peak between the years of 2020 and 2024. Furthermore, the BWMS newbuild demand adds to this work. In addition to IMO’s convention entering into force, the U.S. Coast Guard’s regulation on vessel discharges is expected to boost the BWMS market.

“From our experience the timeline for retrofit project completion requires a minimum of six to eight months. Therefore, the shipowners and operators could face supply issues without scheduling and planning their BWMS installations well in advance of dry-docking and compliance dates. In partnering with our customers to provide a wide range of support from BWMS technology to hands-on maintenance service, we aim to increase operational reliability," said Markus Ljungkvist, general manager, project sales, Wartsila Services.

Ensuring the safety of the equipment and operational availability

In addition to technology alternatives, Wartsila’s offering comprises capability to deliver retrofit projects extends from equipment to full EPC (engineering, procurement, construction) deliveries. Wartsila’s scope of retrofitting ballast water management systems can include, for instance, the equipment, feasibility studies, in-house engineering expertise, installation, advisory and OEM (original equipment manufacturer) life cycle support.

“A single solution provider adds to the efficiency of retrofit projects and minimizes the risks and time needed for retrofitting BWMS, thus optimizing operations and enabling growth for our customers. It also provides shipowners and operators with cost predictability,” Ljungkvist said.

Wartsila provides training for the users to operate the ballast water management system correctly. Training centers around the world and customized trainings at the customer site improve overall awareness, theoretical knowledge and hands-on skills needed to secure BWMS operation and maintenance.

Click here for more information.