The rotted wood and rust-eaten remains of two dam wickets, lying on display on the bank of the Ohio River near Olmsted, Ill., tell the story of compromised infrastructure eating at the core of the nation’s inland river system and its economy.

The relics provide a fitting coda for the Olmsted Locks and Dam project, an endeavor that has seriously challenged the phrase “everything must come to an end.” Three decades of delays, cost overruns and grumbling have plagued Olmsted, the largest and most expensive inland waterways project in U.S. history, but the labor is about to bear fruit.

At a media tour of the site on July 25, Col. Antoinette Gant, Louisville District commander for the U.S. Army Corps of Engineers, declared that the new locks and dam at mile marker 964.4 will officially open to commercial traffic in October. The new infrastructure will replace the crumbling and unreliable Locks 52 and 53, which were completed in 1929. Lock 53 is 1.8 miles upriver and Lock 52 is 25.5 miles upriver.

|

|

The towboat Steve Golding guides four empty tank barges through the Olmsted Locks in late July. The 1,200-foot chambers were completed in 2004 and have been used intermittently as construction continued on the dam. |

|

Brian Gauvin |

With an endgame clearly in sight, Gant expressed the relief felt by the Corps, the inland river industry, farmers and energy producers when she exclaimed, “Never fear, Olmsted is near.”

The site, 43 miles from the riverboat hub of Paducah, Ky., and 17 miles upstream from the Ohio’s confluence with the Mississippi River at Cairo, Ill., is a critical passage in the nation’s inland waterway system. Ninety million tons of corn, grain, petroleum and other products traverse this stretch of the Ohio River annually, including 25 percent of the coal that supplies the eight states on the Mississippi River. Farmers depend on the Ohio to get their crops to the Port of New Orleans and out to the world.

Federal funding for the Olmsted project was approved in 1988. The budget was $775 million and the project was scheduled for completion in 2008. Ten years later, the estimated cost has spiraled to just short of $3 billion. The Corps has attributed the cost overruns and construction delays to restrained annual funding, inflation, poor river conditions for construction, and a low initial cost estimate for the dam.

|

|

Five Tainter gates between the two locks and the wicket dam regulate the flow of water when all of the wickets are raised to fill the upstream pool. |

|

Brian Gauvin |

Mick Awbrey, the Corps’ deputy chief for the Olmsted Division, explained that the decision in the 1990s to utilize the innovative and untried “in-the-wet” construction method for the dam was another factor that increased the project’s cost. The approach was chosen over the traditional cofferdam method because it had the potential to cause fewer closures on the busy river, said Waylon Humphrey, deputy chief of operations with the Corps’ Louisville District.

“In-the-wet” construction requires massive concrete sills to be precast on land and transported on the river to the site, where they are set into place. An enormous amount of engineering was involved at Olmsted, and expensive on-site equipment had to be constructed to facilitate the fabrication and transportation of the concrete components.

The Corps has weathered a barrage of criticism for the cost and perceived inefficiencies of the project, which for years siphoned off the lion’s share of money for infrastructure construction and repair from the Inland Waterways Trust Fund (IWTF). Until 2013, funding for the project was a 50/50 split between federal general Treasury money and the IWTF. In October of that year, funding was increased to $2.92 billion, and the 50/50 cost-sharing ratio was changed to 75/25 for 2014 and to 85/15 thereafter.

The revised cost sharing and increased budget lengthened the construction season from six months to eight or nine months, through low water and high water. More favorable river conditions and adjustments in the process from lessons learned accelerated the progress. The cost-sharing change also allowed the IWTF to fund much-needed infrastructure projects sitting on the back burner while Olmsted gouged its budget.

Representatives from the inland barge industry and agriculture associations joined the media tour in July. Gant announced that construction was essentially complete, although removal of the old locks will push the official date to 2022.

The announcement was cathartic for inland river operators and the agricultural industry. For the past 30 years they have been patient while their tows have stalled, eating at their bottom lines. The brave new world of “just in time” inventory, dependent on reliable and predictable scheduling, fell victim to archaic infrastructure.

|

|

Waylon Humphrey of the U.S. Army Corps of Engineers’ Louisville District describes the operation of Olmsted’s new dam wickets at the facility’s test pit. |

|

Brian Gauvin |

“This is a big project for the industry,” said Martin Hettel, chairman of the Inland Waterways Users Board and vice president of government affairs at American Commercial Barge Line. “Because of the poor condition of the current locks, it can take up to 72 hours to raise the dam at Lock 52 compared to 18 hours years ago, which causes long waits for barges. Locking through can take up to two hours. When Olmsted is operational, locking time will be reduced to an hour or less.”

Hettel explained that Olmsted’s two 1,200-foot chambers also allow for northbound and southbound tows to lock through at the same time, a huge improvement over the old locks upriver.

“There are some shippers in our industry that are avoiding coming up from New Orleans on the Mississippi River because they don’t want to go through 52,” Hettel said. “They are sending their tows from New Orleans through Mobile and up the Tenn-Tom (Tennessee-Tombigbee Waterway) to the Ohio to avoid the risk of delays at Lock 52. It’s more expensive for them and less efficient. The sooner we can get Olmsted operational, the better the reliability is for the economic engine of this inland water system. The key is reliability.”

|

|

The 10-by-40-foot steel panels are a substantial upgrade from the wooden wickets that were used for decades on the deteriorating locks upriver. |

|

Brian Gauvin |

John Eckstein, president and chief executive officer of Marquette Transportation Co., said that although the company’s operations are concentrated on the Mississippi River, they are indirectly affected by closings on the Ohio because of the interrelated nature of moving cargo on the inland river system.

“The river system is the flywheel driving the agricultural industry in this country and a national treasure that we need to keep up,” said Chris Boerm, president of transportation at Archer Daniels Midland. “The inland waterway system with the lock and dam system, combined with the truck and rail networks, set the U.S. apart from the rest of the world.”

The Corps, the federal agency responsible for maintaining navigation on the nation’s rivers, has calculated that delays in completing the project have resulted in $640 million to $800 million in lost benefits to the U.S. annually. The calculation is an estimate of the reduced cost of river-related business if the Olmsted project was operational. Rail and road transport also were factored in.

|

|

Col. Antoinette Gant, Louisville District commander for the U.S. Army Corps of Engineers, details progress at Olmsted during a media tour of the site in July. |

|

Brian Gauvin |

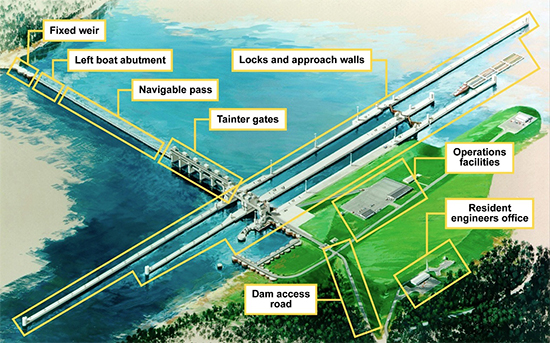

The locks adjacent to the Illinois bank are 1,200 feet long and 110 feet wide. The chambers were built in a dry cofferdam and completed in 2004. The dam is composed of five Tainter gates, 1,400 feet of boat-operated wickets and a fixed weir abutting the Kentucky bank.

The scale and precise tolerances required to build the system dragged on the project timeline. Due to the unknowns and risks presented by the deep and fluctuating river, no contractor bid a fixed price on the project, forcing the Corps to adopt a cost-plus contract structure.

The Tainter gates regulate water flow when the 140 wickets are all raised at low water to fill the upstream pool and the tows lock through. During high water, the wickets are down to allow the tows to bypass the locks and pass over the dam.

|

|

The new Olmsted Locks and Dam extends from the lock chambers on the Illinois side of the Ohio River to a fixed weir on the Kentucky bank. At high water, the facility’s 140 wickets are lowered and tows pass over the dam at the navigable pass. |

|

U.S. Army Corps of Engineers illustration |

Each Tainter gate consists of a sill shell, stilling basin shell and a lower pier shell. Twelve additional shells make up the navigable pass that contains the wickets (see illustration above).

The precast concrete shells are 2 feet thick with a waffle pattern on the underside to keep the weight down for transport. Each shell weighs between 2,600 and 3,700 tons. Concrete has almost no tensile strength, requiring the shells to be moved carefully to prevent cracking. If one had cracked, the replacement cost would have been $7 million and more time would have been lost to fabricate a new one.

|

|

Crews at Olmsted in late July dismantle the world’s largest catamaran barge, which was purpose-built for the “in-the-wet” method used to construct the new dam. Massive concrete sills were precast on land, then transported on the river to be set into place. |

|

Brian Gauvin |

Despite all of the frustration, delay and expense, Kevin McLaughlin, a senior project director for Olmsted contractor AECOM, said the number of innovations generated by the “in-the-wet” process resulted in “a wonder of modern construction.” No longer an unknown, the method will be used on other designated Corps projects.

“Olmsted is a critically important project to carriers, to shippers, and frankly, to our national economy overall,” said Debra Calhoun, senior vice president of the Waterways Council Inc. “Olmsted’s opening represents modernization on the inland waterways transportation system, and like most priority navigation projects, will provide a great return on investment. Sixteen dollars in annual net economic benefits to the nation are generated by Corps of Engineers’ Civil Works mission projects for every $1 expended.”

In a test pit at Olmsted, down the bank from two relics salvaged for display from the antiquated Locks 52 and 53, stands a new 10-by-40-foot steel wicket. A symbol of strength and progress, it provides the concluding chapter in a 30-year story.