At mile marker 783 on the Arkansas bank of the Mississippi River, Mid-River Terminal has two deck barges, one with a crane aboard, the other providing moorage for two towboats: the 67-foot Joe Ellis, named for the father of the company’s owner and president, Rick Ellis, and the sparkling new 70-foot Dianna Lynn, named for the owner’s wife.

Both towboats hail from Bayou La Batre, Ala. Joe Ellis was built in 1975 at Master Marine and Dianna Lynn, delivered this spring, was built at Rodriguez Shipbuilding.

Also new, on the hill overlooking the river is a building complex with three large truck bays sided by a two-story structure housing Mid-River’s offices. Ellis broke ground on the company’s 100-acre riverfront location in 2014. Adjacent to the building are truck scales, piles of aggregate and huge 70-ton Komatsu trucks coming and going.

|

|

Willie Stamps steers the boat upriver from the dock to pick up a pair of hopper barges. |

Mid-River’s location is a mere 1.6 miles from Big River Steel, a new and innovative steel mill that, when in operation this fall, will be rendering scrap metal into steel coil, utilizing the first Flex Mill process in the world. The two companies point to a brighter economic future and a much-improved employment climate for Osceola, Ark., a rural agricultural town some 50 miles north of Memphis.

“Big River is tooling up to start phase one this fall,” Ellis said. “They are projecting 1.8 tons of steel coil the first year and 3.6 tons with phase two. We’ll handle the barges of scrap and the steel coils that Big River manufactures from it.”

That is when Mid-River’s trucks, cranes, Joe Ellis and Dianna Lynn will shift into high gear.

Dianna Lynn is the first newbuild vessel Ellis has undertaken and, by his account, it was a great experience. “(Joey) Rodriguez did a great job,” Ellis said. “He is a prince of a fellow, salt of the earth. We have a good working relationship and he did a great job, and it’s a great handling boat.”

|

|

Dunkin prepares to tie up the 70-foot towboat as it heads for the dock. |

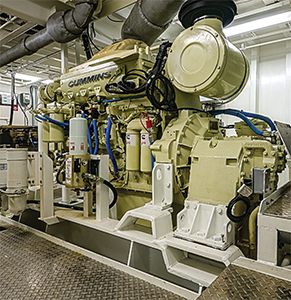

The new 70-by-30-foot vessel has a tunnel stern. Rodriguez explained that he began building tunnel sterns into his shallow-draft pushboats some years ago. Dianna Lynn, with an 8-foot operating draft, is powered by three six-cylinder, 660-hp Cummins QSK19 engines with ZF gears at a 6:1 reduction ratio. The gears turn 66-inch stainless steel propellers.

“I’ve always liked triple-screw propulsion because if you run into a problem with one engine, you still have two-thirds of your power,” Ellis said.

Upon gaining the pilothouse of Dianna Lynn, the first impression is of space, light and the visibility provided by 360 degrees of window stretching from just above the floor to the ceiling. Capt. Willie Stamps, steering Dianna Lynn to a pair of hopper barges that needed moving, got to the point.

|

|

Dianna Lynn’s bridge console, designed by Mid-River port captain Jody Smith, allows the helmsman to conduct all boat operations without standing up. |

“I love this pilothouse and I love this boat,” he said. “It’s roomy, it’s smooth, it’s pretty quiet, it’s very comfortable.” Stamps, who has been working on the river since 1992 and has had his pilot’s license since 2000, added, “It’s got everything you want in a boat. It’s the smoothest harbor tug I’ve ever been on.”

The layout was drawn up by Mid-River’s port captain, Jody Smith. “He set it up the way he wanted it and had Rodriguez build it to his design,” Stamps said.

The console is lower than is typical on a pushboat, and it is laid out simply and logically. The vision forward is expansive and a monitor, fed by 11 closed-circuit cameras, puts eyeballs on all the other sectors of the vessel.

“The console layout gives excellent visibility and everything is within reach,” Stamps said. “You can run this boat without ever having to stand up.”

|

|

Mate William Dunkin pulls on the face wires while making up a two-barge tow. |

The pilothouse, with a 31-foot height of eye, is set atop two accommodation decks and a bridge electronics deck that actually has headroom compared to the crawlspace shoehorned between many workboat decks. The steering and flanking rudders are controlled from the pilothouse, with mechanical shafts through the houses connected to the hydraulic actuator valves in the engine room.

The galley is on the second deck, a feature that Stamps says is a real bonus, making it easier for the pilot to access the bridge from the galley and vice versa. All of the tanks are zero discharge for storing treated sewage, drained graywater and potable water. A separate tank handles waste oil.

As Stamps approached the barges, he eased Dianna Lynn’s push knees, faced with Schuyler rubber fenders, up to the stern of the tow and lined up on the centerline. The mate, William Dunkin, muscled the face wires over the barge bitts, and Stamps engaged the Wintech deck winches to snug them up. Stamps then backed the tow downriver several hundred feet and sided up to the Mid-River deck barge.

|

|

One of three Cummins QSK19 mains that power Dianna Lynn. Mid-River owner Rick Ellis likes the redundancy provided by triple-screw propulsion. |

Back at the office, Ellis explained that the bulk of Mid-River’s work is cutting barges out of the large line-haul tows plying the river for companies such as Ingram, ACL, Marquette and Western Rivers Boat Management, and moving them to the Mid-River fleet. They are then offloaded, cleaned if necessary and placed back in the fleet, ready for pickup by the northbound tows. In addition to fleeting, Mid-River services a number of grain docks in the area, and has a barge cleaning operation.

“We’re not a line boat company,” Ellis said. “We provide harbor services and stevedoring. It’s what we are. I’ve thought about getting into the line-haul business but it’s a dog-eat-dog world out there.”

Mid-River also handles a significant amount of aggregate, barging it and trucking it. “We are pretty self-sufficient,” said Ellis, who also owns Ellis Processing and Material Handling at mile marker 724 on the river, a few miles south of Memphis. At that location Ellis has two boats: David Stone, named for Ellis’s best friend, and Ground Zero, which commemorates the 9/11 attacks. Their role is similar to the Mid-River boats and they also serve Nucor Steel.

|

|

Dunkin, left, and Stamps take a break in front of Dianna Lynn’s spacious pilothouse. Mid-River plans on adding another new boat when the economy improves. |

Ellis has been stevedoring since 1987 and has spent many years on the river, 10 of them as a pilot. He does not miss life on a churning tug looking at the stern of a tow for 30 days at a stretch.

“But owning boats and working on river operations is exciting and I can still go out on one of the boats and play if I want to,” he said. He is applying for a three-state construction license that would allow him to handle marine construction projects in Arkansas, Tennessee and Mississippi.

“I plan on building another boat when the economy improves,” he said.

That time might not be too far in the future as Big River Steel proceeds through phase two of its operation. Ellis confirmed that when the conditions look right, he will build the boat at Rodriguez Shipbuilding.