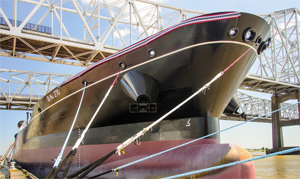

Capacity is an obvious focal point when designing an articulated tug-barge (ATB). Of late though, the correlation between speed and fuel efficiency has muscled into the equation. Case in point is the 150-foot tug Kim M. Bouchard and the 628-foot, 250,000-barrel barge B. No. 270.

Designed by Guarino & Cox of Covington, La., the tug and barge were built at VT Halter Marine’s yard at Pascagoula, Miss., and delivered in July 2015. The identical Donna J. Bouchard and B. No. 272 were scheduled for delivery in the first quarter of 2016.

“The vessels were designed around the answers to questions from our customers,” said Capt. Bill Lawton, project manager for new construction for Bouchard Transportation. “Two of them being, ‘What will be your speed and what is your fuel efficiency?’” The equipment that Bouchard has chosen to drive and couple its ATB fleet includes EMD propulsion, Nautican wheels, John Deere auxiliary power and Intercon’s coupling system.

The propulsion chain is two EMD 20-710 Tier 3 mains at 5,000 hp each with Lufkin RS4100 reduction gears at a 6:1 ratio. “The EMDs are very fuel efficient,” said Lawton. “And it’s all Nautican aft of the shafts.” The Nautican equipment consists of 148-inch fixed-pitch, four-blade, stainless-steel wheels in Nautican nozzles and triple rudders.

There are three John Deere 6090AFM75 200-kW 480V generators and a John Deere 6068AFM85 150-kW 480V emergency generator.

To marry the tug and the mega-size barge, Intercon supplied one of its largest coupler ship sets, fabricated with 64-inch pins and lightering plates. Lawton explained that historically Bouchard fitted its ATB tugs with a backup Intercon towing winch on the stern, a precaution against the tug’s coming out to the notch. Over the years the company has developed so much confidence in the Intercon coupler that it chose to go without the backup winch on the new tugs.

|

|

The boat’s captains, Eric Fels and Guy Berry, with the state-of-the-art electronics in the wheelhouse. |

“The towing winch just doesn’t get used on these boats,” said Lawton. “It didn’t seem reasonable to do the maintenance on a towing winch when we have such a proven system.”

Another factor contributing to the fuel efficiency — and the 12- to 14-knot speed — of the ATB is the bulbous bow on the barge. “It makes for more of a ship hull that increases the speed and the fuel efficiency,” said Lawton.

Kim M. Bouchard is double hulled and classed ABS + 1 Towing, SOLAS and class FiFi-1. The firefighting system is an FSS monitor, forward on the superstructure tower, that is driven by an Aurora 421 fire pump delivering 1,300 gpm.

There are nine boat crew and five tanker crew housed in five single and five double staterooms.

The tug is equipped with a Hyde ballast water treatment system. Intended for service in the Gulf of Mexico and along the Atlantic Coast from Corpus Christie, Texas, to Maine, both Kim and Donna are capable of going worldwide.

Summing up the project, Lawton said, “We’ve hit everything we expected to hit.”

|

|

|

|

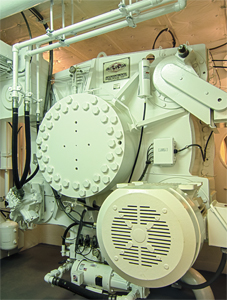

Kim M. Bouchard chief engineer Daniel Rose and assistant engineer Thomas Sippel with an EMD 20-710 main engine. |

One of the boat’s gear-driven ram assemblies. |

|

|

|

|

|

The barge’s notched channel for the Intercon pin. |

Kim M. Bouchard’s FFS fire monitor on the superstructure tower. The vessel is classed FiFi-1. |

|

|

|

|

|

The teeth of a steel connecting head on the tug. |

The barge portion of the ATB is the 628-foot B. No. 270. |