Canada’s Transportation Safety Board (TSB) has determined that the separation of a flexible fuel hose and a copper tube, which were held together only by a clamp, spilled diesel onto generator components and ignited an engine room fire on a British Columbia tugboat.

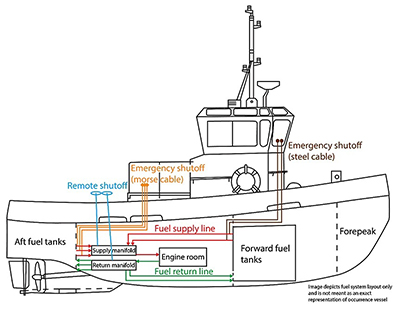

At approximately 2230 on July 11, 2016, the 40-foot Ken Mackenzie caught fire while towing a log boom on the Fraser River. Unable to contain the fire, the master shut off the main engines from the wheelhouse and activated the emergency shutoff for the two forward fuel tanks. Just before abandoning the vessel, he shut off the fuel supply and return valves to the engine room from the main deck.

The master and deck hand abandoned ship to the log boom and were picked up by the assist tug Harken No. 5. The fire was extinguished with the assistance of the tug Pacific Tyee and Harken No. 9. There were no injuries.

When the evening crew of Ken Mackenzie boarded at 1900, the day-shift crew informed them that there was an odor of diesel on the vessel, but no one had been able to find the source. The day crew completed a domestic safety management report but did not transmit it to the office of the operator, Harken Towing Co. of Port Coquitlam, British Columbia, because it was after business hours.

The night-shift deck hand conducted a routine safety round in the engine room soon after the crew change and looked for leakage that could explain the smell of diesel. Finding none, the crew continued operating the vessel.

TSB investigators traced the source to piping that returned diesel fuel from the generator fuel pump to the fuel oil tank. The piping consisted of a 6-mm flexible fuel hose and an 8-mm copper tube connected by a hose clamp. The copper tube was smooth and did not have serrations or a bead at the end. The connection separated and fuel sprayed onto components of the generator, starting the fire.

Investigators also determined that the cables used for the aft fuel tanks’ emergency shutoff valves seized in the conduit, making it impossible for the crew to shut off the fuel system. The cables were not designed to withstand elevated temperatures prevalent during a fire.

|

|

An illustration provided by the Transportation Safety Board of Canada depicts the fuel system layout on Ken Mackenzie. |

|

Courtesy TSB |

In a written reply to a query from Professional Mariner, Harken Towing stated that in repairs to the vessel after the incident, stainless-steel supply and return lines were installed to the generator with JIC (Joint Industry Council) fittings.

“The emergency fuel tank shutoffs were run using stainless-steel cable going through stainless-steel tubing as sheathing,” Harken’s port engineer wrote. “The fire was a result of a leaking fuel return hose at the connection point to the auxiliary engine. The hose was previously made of fuel-rated rubber.”

The TSB said that a new generator and fittings installed on Ken Mackenzie in 2009 were not inspected or certified by Transport Canada or a similar authority (a classification society or manufacturer’s representative) before being put into service. “An inspection or certification is not required under current regulations for this class of vessels,” the agency said.

The TSB also noted that if components for emergency equipment and machinery “are installed or replaced by personnel without adequate guidance or knowledge of industry standards, and such equipment is subsequently put into service without being inspected by a competent person, there is a risk that the installation will be unsafe.”

The report stated that if “adequate regulatory oversight” is not applied to tugboats of less than 15 gross tons, “instances of unsafe equipment and operating conditions may continue to occur, putting people, assets and the environment at risk.”

Following the Ken Mackenzie incident, the TSB issued safety letters to Transport Canada and the vessel owner, Tidal Towing Ltd. of Port Coquitlam, to provide information about the shortcomings of the control cables used to operate emergency shutoffs for the fuel tanks.

Damage to the tug included “significant burning and charring” of materials in the engine room, the TSB said. Heat from the fire also melted or burned components directly above the generator and distorted some deck plating. A monetary estimate of the repairs was not available.