Archer Daniels Midland Co. has ordered three grain carriers that will employ air-bubble technology to decrease hull resistance through the water as a way of cutting fuel costs and greenhouse gas emissions.

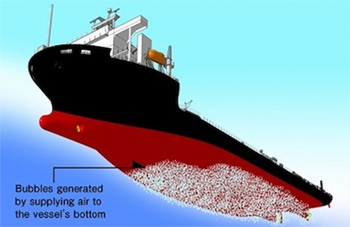

The air-bubble technology was developed by Mitsubishi Heavy Industries, Ltd. Called the Mitsubishi Air Lubrication System, it reduces friction between a vessel's hull and seawater by means of air bubbles produced along the vessel's bottom.

|

|

Archer Daniels Midland has ordered three 777-foot bulk carriers to be built by Oshima Shipbuilding Co. of Nagasaki, Japan. Air bubble technology, along with other fuel-saving features, will reduce the ships' CO2 output by about 25 percent. (Photo courtesy Mitsubishi Heavy Industries) |

The new technology, combined with other elements of the ships' designs, will allow the ships to cut their CO2 emissions by 25 percent compared with conventional bulk carriers.

The first commercial application of the air-bubble system will be in the three grain carriers. Sumitomo Corp. of Japan received the order from Archer Daniels Midland for the ship construction, while Oshima Shipbuilding Co. Ltd. of Nagasaki was selected to actually build the ships.

The three grain carriers will be 95,000-dwt vessels. Designed as post-Panamax ships, they will be 777 feet long with a beam of 131 feet. Thus, they will be able to travel through the Panama Canal after its planned expansion is completed in 2014.

The air in the friction-reduction system is produced by motor-driven blowers and collected in large-diameter pipes. Then the air is distributed by individual branch pipes and delivered through air chambers mounted on the bottom of the hull. The air-lubrication system results in the vessel being able to go faster with less horsepower. The lower power requirements to achieve a given speed results in lower fuel consumption and CO2 emissions.

To confirm the benefits of the system, Mitsubishi conducted computational fluid dynamics modeling and carried out full-scale mockup water tank testing. It also installed a prototype system on Yamatai, a module carrier (a specialized ro-ro vessel for transporting large prefabricated structures) operated by NYK-Hinode Line.

Mitsubishi is offering the technology for use in very large crude carriers, bulk carriers and other ships. The researchers found that there was a negligible loss of propulsive efficiency due to air bubbles because the bubbles flowed along the ship bottom toward the area above the propellers rather than through them.

These three grain carriers will also feature a newly-designed bow to reduce wave-making resistance. They will also have a system that improves propulsion efficiency by positioning fins forward of the propellers and placing grooves in the propeller boss cap. The ships will have a relatively shallow draft of 41 feet, which will also contribute to energy savings and CO2 reductions.