With its tapered hull and spider-like pilothouse, Capt. Cooper is a unique boat with an important job.

Bald Head Island Limited developed the 850-hp vessel to push a deck barge between mainland North Carolina and the resort island located four nautical miles away. The two-vessel unit makes four round trips a day carrying virtually all large cargo and provisions for the island’s visitors and full-time residents, a number that can swell to 5,000 during the high summer season.

CT Marine of Portland, Maine, designed the 50-by-24-foot vessel. Capt. Cooper was the first ever self-propelled vessel project for shipyard Metal Trades Inc. in Hollywood, S.C. Delivery came in August 2017.

Capt. Claude McKernan, manager of Bald Head Island Limited’s Barge Department, said the new tug was developed for simplicity and efficiency. Pushing the 100-by-34-foot barge USS Brandon Randall is its sole job. Given the short runs, the tug was built as a day boat without crew accommodations. And with facilities at both ends of the route, it also lacks a head.

“This was conceived to be reliable, safe and maintenance-free,” he said in a recent interview. “We have reduced maintenance points wherever we could on the boat.”

|

|

The two vessels make four round trips a day carrying cargo and provisions for the resort island. |

|

Rob Wright |

Capt. Cooper replaced the 42-year-old Capt. Alex, a tug that required increasing upkeep in recent years. Bald Head Island runs one tugboat, so unscheduled lost time means canceled transits or hiring an outside tug at great expense. Ferries carry people to the island, which does not allow personal vehicles.

“We had been pushing for a new tugboat for a while because it’s the only one we have, and if it breaks down or needs major maintenance we don’t have a standby tug and the island tends to run low on essentials, including provisions, construction supplies and needed equipment,” McKernan said, adding, “We knew we needed a newer, more reliable vessel.”

The seemingly mundane route from Southport, N.C., to Bald Head Island across the Cape Fear River has some challenges. Tidal currents exceeding 4 knots can push perpendicularly against the vessels as they approach the island’s jetties. Once inside, a hard-starboard turn is required in tight quarters to line up for the landing.

These features necessitated Capt. Cooper’s unique hull and superstructure, as well as its advanced steering system, explained naval architect Christian Townsend, who developed the tug’s plans with his father, Corning Townsend.

The Townsends initially planned Capt. Cooper to have an 18-foot beam. But further analysis suggested additional width was required for stability. Yet the confined harbor made a 24-foot beam impossible. The design firm solved this problem by creating a tapered hull that’s 24 feet wide amidships and just 17 feet at the transom.

|

|

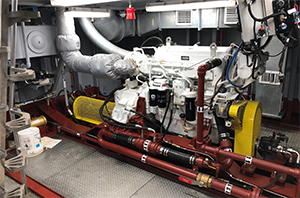

Propulsion aboard Capt. Cooper comes from twin John Deere Tier 3 mains. |

|

Bald Head Island Limited |

“They literally couldn’t swing the stern in if it was any wider at all, but they needed the width of the boat forward for stability and greater twisting torque for maneuvering the barge,” Christian Townsend said.

Meeting the 5.5-foot draft requirement was another challenge. Designers chose an aluminum superstructure encompassing everything from the main deck up. All of the aluminum was left bare to reduce maintenance.

Even so, the vessel was still too heavy, so the upper house walls were removed. Four structural supports hold the pilothouse eight feet above the lower house.

The novel design is not unique to Capt. Cooper, but it remains something of a rarity in the U.S. and around the world. Over time, the look has earned the nickname “spider house,” Christian Townsend said. “It’s kind of sticking, I guess.”

CT Marine’s design also called for flanking rudders, which focus extra thrust for precise turns like those approaching the landing on Bald Head Island. The flanking rudders go 45 degrees hard-over instead of the 35 degrees typical on a similar pushboat. All told, Capt. Cooper has eight rudders.

The new tug also maintains the same 26.5-foot height of eye as Capt. Alex for a consistent vantage point over the barge.

“It’s been doing real well. It’s a big step up for us,” said Capt. Rusty Terry, who likened the new vessel to replacing a 1976 Subaru Brat with a brand new Chevrolet pickup.

“We have eight rudders on here … four flanking and four main rudders. The maneuverability is real good and it handles real well,” he continued.

|

|

The deck locker door leads to the main deck upper engine room. |

|

Bald Head Island Limited |

Capt. Cooper cruises at 8 knots with a loaded barge thanks to twin John Deere 425-hp Tier 3 engines turning five-blade nibral props through a ZF gearbox. Electrical power comes from two Northern Lights 40-kW generators. All equipment, including the John Deere 13.5-liter engines, was selected primarily for reliability and ease of maintenance.

The wheelhouse is outfitted with Furuno navigation electronics, while on deck the tug has two Patterson deck winches with synthetic Samson face lines.

Bald Head Island Limited interviewed a handful of shipyards before choosing Metal Trades, located just southwest of Charleston. The yard has been around for 56 years and has a solid reputation for barge construction and vessel overhauls. But until Capt. Cooper it had never built a twin-screw pushboat.

McKernan visited the company’s shipyard and left impressed with its capabilities. Proximity also was a factor in the decision, allowing for regular day trips to the yard to monitor construction. The shorter delivery distance to North Carolina after construction was completed reduced costs compared to a yard farther away.

Around the time Bald Head Island Limited approached them, Metal Trades leaders were already planning to move into tugs and other self-propelled boats. Yard management planned to build a vessel on spec when they won the contract for Capt. Cooper.

|

|

The tight quarters and challenging approach into Bald Head Island necessitated Capt. Cooper’s wedge-shaped hull designed by CT Marine of Portland, Maine. |

|

Rob Wright |

New vessel construction manager John Geiges said Capt. Cooper was a perfect first boat for the shipyard.

The tug, built to Coast Guard Subchapter M standards, also allowed the yard to develop experience with the new regulations. Metal Trades’ electrical supervisor, David Crocker, internally developed the complete electrical drawings for the tug.

“We didn’t suffer a learning curve,” Geiges said in a recent interview.

“We put a lot of planning into it and one thing I am proud of, we never went backward,” he continued. “We never did anything we had to rip out, we always kept going forward.”

Looking back, McKernan acknowledged some reluctance about choosing a shipyard without extensive tugboat building experience. But, speaking almost eight months after delivery, he has no regrets.

“When you take delivery of a brand new custom-built boat, generally you are going to have some issues,” he said. “We have basically had none.”