With larger ships now calling in at many East Coast ports, tugboat operators have responded by building more powerful azimuthing stern drive (ASD) tugboats that are more capable of safely docking, undocking and escorting the massive vessels.

Answering the call, Tony and Alex Savas, owners of Petchem Inc., had Christine S built for the company’s Port Canaveral, Fla., fleet. Boasting 72.5 tons of bollard pull, the 5,000-hp, 80-foot tug packs abundant power for its size.

“It’s crazy nice, that boat,” said Alex Savas. “Everyone in the port is fascinated by the boat and I get nothing but good comments. It’s the most powerful permanent tug in the port.”

The new vessel, named for Tony’s daughter, is the first ASD tug in Petchem’s fleet. It replaces the original Christine S, a 96-foot utility boat with which the company began operations in Port Canaveral in 1983.

|

|

Petchem installed a JonRie InterTech Series 230 hawser winch on the bow. |

The Savas brothers landed a Navy contract in 1984 and added submarine fendering to their fledgling fleet of two older conventional tugs. The original Christine S was assigned the task of transferring submarine personnel. In 2004, after securing a permit to compete with Seabulk Towing in Port Canaveral, Petchem hired Farrell & Norton Naval Architects of Newcastle, Maine, and B&B Boat Builders of Bayou La Batre, Ala., to design and build the conventional tugs Elizabeth S and Michael S. Both were equipped for ship-assist work with a forward H-bitt but no winch.

To rationalize building a new tug with z-drive propulsion and a bow winch, Petchem sold Michael S to Mohawk Northeast of Groton, Conn. Mohawk, primarily a marine construction company, shortened the name to Michael. It also equipped the tug with a JonRie InterTech Series 515 towing winch.

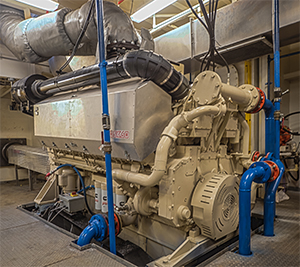

Once again, Petchem engaged Farrell & Norton to design Christine S, and Gulf Coast Steel, formerly B&B Boat Builders, to build the new tug. Christine S is fitted with two 2,500-hp Cummins QSK60 Tier 3 mains and ZF 8000 Series z-drives. Electrical power comes from two John Deere 99-kW units.

“The main design requirement was just to optimize the boat to fit into Petchem’s existing business operation,” said Tom Farrell, senior naval architect at Farrell & Norton. “The horsepower and bollard pull were definitely major factors in the design. The engines and z-drives were chosen by the owner, and we worked the design of the hull around those two major components.

|

|

Capt. Walt Morgan helming Christine S in the Port Canaveral turning basin. |

“Originally we had a little less horsepower and smaller z-drives, but when the decision was made to go with the larger equipment, we had to widen the boat to handle the increased power and size of the units,” he continued. “The increased width also helped meet the stability criteria.”

Christine S is the first tugboat in the U.S. equipped with the huge ZF 8000 drive. These well-mounted z-drives give the tug a wide operational range. It can escort large ships and even Navy submarines, said Ed Schwarz, ZF Marine’s commercial thruster products manager.

The tug’s engineer, Billy Golding, noted the smooth operation and rapid response time of the ZF drives. He also described the spaciousness of the engine room despite the beefy main engines.

“It is so clean and quiet,” Golding said. “At 5,000 hp at 1,900 rpm, these engines are so powerful for being so quiet.”

The bridge was designed around achieving 360 degrees of visibility and the best lines of sights for the operator, Farrell said. The result is great visibility and a surprisingly roomy space with a tight console arrangement that keeps electronics, propulsion and winch controls close at hand. The electronics components include Furuno radars, chart display, GPS and e-nav software. Other electronics include a Koden AIS, Simrad autopilot and Icom radios.

|

|

Propulsion comes from twin 2,500-hp Cummins QSK60 engines. |

Like Elizabeth S, Petchem’s latest tug is equipped with an H-bitt on the bow. But unlike its predecessor, Christine S has a hawser winch on deck. The Savas brothers chose a JonRie Series 230 bow winch wound with 450 feet of Samson 2.5-inch rope.

“The JonRie Series 230 is a ‘super series’ winch, having a larger brake and more drum capacity to handle larger ships,” said Brandon Durar, president of Manahawkin, N.J.-based JonRie InterTech.

The ship set includes JonRie’s auto-tension system and an active heave compensation system utilizing a controlled freewheel option. The line pull of the winch is 30,000 pounds with a line speed of 100 fpm. The brakes are rated for 600,000 pounds.

The winch’s foot pedal controls are a notable safety feature, according to Capt. Rusty Vasbinder.

|

|

Christine S is the first U.S. tug with ZF 8000 z-drive units. |

“It’s a great winch and having the foot pedals is very handy because you have your hands full while maneuvering,” he said. “After the deck hand gets a line up on a ship, he can then get out of the way. He isn’t in the bite of the line and can get away from it when it’s working.”

Vasbinder and fellow Capt. Walt Morgan found much to like on Christine S.

“It’s a sturdy and stable boat that is built very well,” said Vasbinder. “The electronics work very well and the (closed-circuit) system with four cameras is great for monitoring everything aboard. And this boat, with the Cummins engines, is so quiet and fun to drive. It’s a blast.”

“I love running this boat,” said Morgan, adding, “I like everything it does, the way it handles, and whatever you ask it to do, it does.”